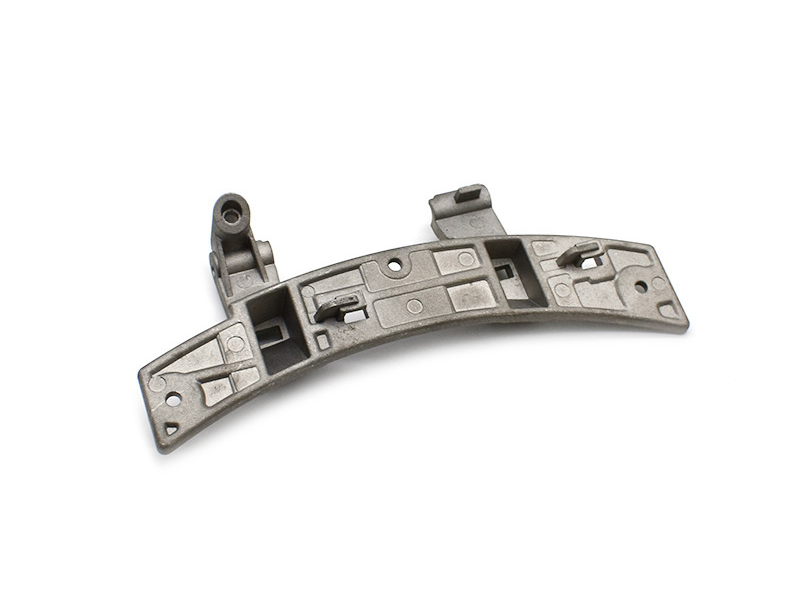

Custom Brass Die Cast Mechanical Transmission Wheel Hardware Applications

Mechanical transmission systems often rely on precision components such as gears, hubs, sprockets, and wheels to transfer motion, torque, and power. In harsh operating conditions, these parts must offer high dimensional accuracy, wear resistance, and corrosion protection. Brass die casting is a robust and cost-effective manufacturing solution for producing these components with high repeatability and built-in design complexity.

At Neway, we provide brass die casting services for mechanical hardware used in gear trains, drive systems, industrial automation, and motorized assemblies. With advanced tooling and process control, we produce high-strength transmission components with tight tolerances and ready-to-assemble surfaces.

Why Brass is Ideal for Transmission Wheels and Gears

Brass alloys are particularly well-suited to mechanical transmission applications due to their excellent machinability, wear resistance, and corrosion protection. In rotating systems, brass parts minimize friction, dampen vibration, and operate with minimal maintenance under continuous load conditions.

Key Performance Benefits

Tensile strength: 350–550 MPa depending on alloy

Wear resistance: superior galling resistance compared to aluminum or zinc

Dimensional tolerance: ±0.02 mm for gear pitch circles and shaft bores

Surface roughness: Ra ≤ 1.6 µm after polishing or post-machining

Corrosion resistance: suitable for humid, dusty, or industrial lubricant environments

Brass also offers thermal and acoustic damping, making it ideal for minimizing noise and heat buildup in enclosed gearboxes and transmission housings.

Typical Brass Die Cast Components in Mechanical Transmission

Brass die casting enables production of rotary hardware with integrated structural and alignment features. It supports multi-axis designs, tight gear meshes, and surface finish requirements for high-efficiency power transmission.

Component Type | Application Examples | Key Requirements |

|---|---|---|

Spur and Bevel Gears | Gearboxes, machine drives, rotary positioning systems | Precise tooth profile, surface hardness, tight axial tolerance |

Drive Wheels | Small motor drives, conveyor rollers | Concentricity, balance, wear resistance |

Hub Flanges | Pulley mounts, rotary couplings | Keyway strength, torque resistance, alignment fit |

Gear Blanks | Pre-machined gears for post-hobbing | Density control, machinability, dimensional stability |

Rotary Indexing Plates | Stepper motor wheels, mechanical timers | Tooth alignment, vibration damping, repeatability |

Brass Alloys for Transmission Components

Neway uses a range of brass alloys that combine strength, wear resistance, and precision casting properties. All alloys meet ISO 4261 and ASTM B584 standards for mechanical hardware and gear casting.

Alloy | Copper (%) | Zinc (%) | Tensile Strength (MPa) | Best Use Cases |

|---|---|---|---|---|

~61 | ~35 | ~345 | CNC-machined gear blanks, hubs with threads | |

~58 | ~38 | ~400 | Small gears, drive wheels, rotary plates | |

~62 | ~36 | ~480 | High-strength gears, marine equipment gears | |

~60 | ~40 | ~420 | Wear-resistant transmission and clutch components |

Alloys are selected based on gear tooth load, surface finish requirement, and secondary machining or plating steps.

Dimensional Precision and Fit

Precision is essential in transmission wheel hardware. Poor tolerances can cause misalignment, gear backlash, or premature failure. Neway maintains tight quality control across high-volume brass casting runs.

Gear profile tolerance: up to DIN 8 (fine precision)

Shaft hole tolerance: ±0.02 mm for press-fit or keyed hubs

Concentricity: ≤ 0.03 mm between bore and OD

Gear tooth finish: Ra ≤ 1.6 µm post-machining

Weight variation: <1.5% across cavity set

Parts are validated using gear profile testers, CMMs, and roundness gauges. We also offer CNC post-processing for fine tooth shaping or pilot bore creation.

Surface Finishing and Wear Protection

Transmission components are exposed to friction, oil mist, and in some cases, moisture or particulate-laden air. Neway offers advanced surface finishing to improve durability and performance.

Electroplating: tin, nickel, or chrome plating to reduce friction and resist oxidation

Powder coating: colored protective layers for identification and corrosion resistance

Painting: for anti-corrosion primers or visual tracking marks

Tumbling: deburring and polishing for smooth rotation and meshing surfaces

Assembly: installation of pins, keyways, or threaded studs

Surface finishes can meet ASTM B117 (salt spray), ISO 9227 (coating adhesion), and RoHS environmental compliance standards.

Tooling and Production Capabilities

Neway’s tool and die making services are tailored for precision gear and wheel casting, including multi-cavity molds and high-wear inserts for fine-profile molds.

Tool steel: H13 hardened steel for long-run gear dies

Tool life: 150,000–400,000 shots for brass alloys

Shot cycle time: 25–40 seconds

Cavity control: <0.03 mm variation in gear OD between cavities

Rapid prototyping: for early-stage transmission prototyping or part validation

Low-volume and mass production programs are available, with integrated traceability and batch inspection.

Case Study: Brass Indexing Gear for Automation Assembly Line

An industrial automation company needed a custom gear wheel for a pneumatic indexing module. Requirements included:

72-tooth spur gear with 120 mm OD

DIN 9 gear tolerance, 0.02 mm bore tolerance

Operating torque: 30 Nm

Service temperature: 5–60°C with mist lubrication

150,000 units annually

Neway selected Brass 380 for balance of wear resistance and machinability. A 2-cavity hardened die was used. Post-casting, each gear was CNC machined for final bore and flatness. Nickel plating was applied for long-term oxidation protection. Yield exceeded 99.3% over the first three production batches.

Why Mechanical OEMs Choose Neway

Neway delivers consistent quality and engineering flexibility for precision die cast rotary hardware:

End-to-end control from alloy casting to machining and assembly

ISO 9001:2015-certified process control with inspection traceability

Support for gear profile optimization, torque calculations, and application matching

Cost-effective tooling options for modular product lines

Global delivery capabilities with JIT or VMI inventory support

Whether for robotics, drive systems, industrial automation, or HVAC dampers, Neway ensures your mechanical transmission components meet the demands of modern motion systems.

Conclusion

Brass die casting provides an optimal balance of strength, precision, and corrosion resistance for rotary transmission components such as gears, wheels, and hubs. With tight tolerances, low-friction surfaces, and efficient mass production, Neway helps mechanical OEMs reduce cost and improve system reliability. From initial design to final assembly, our copper alloy expertise and die casting capabilities support your most demanding motion hardware applications.

To start your custom mechanical transmission hardware project, contact Neway today.

FAQs

What brass alloys are best for precision gear and wheel die casting?

How does brass compare to steel or aluminum for small mechanical transmissions?

What tolerances can be achieved for gear pitch and bore alignment?

What surface finishes are recommended for reducing gear wear?

How fast can prototypes be delivered for custom gear projects?