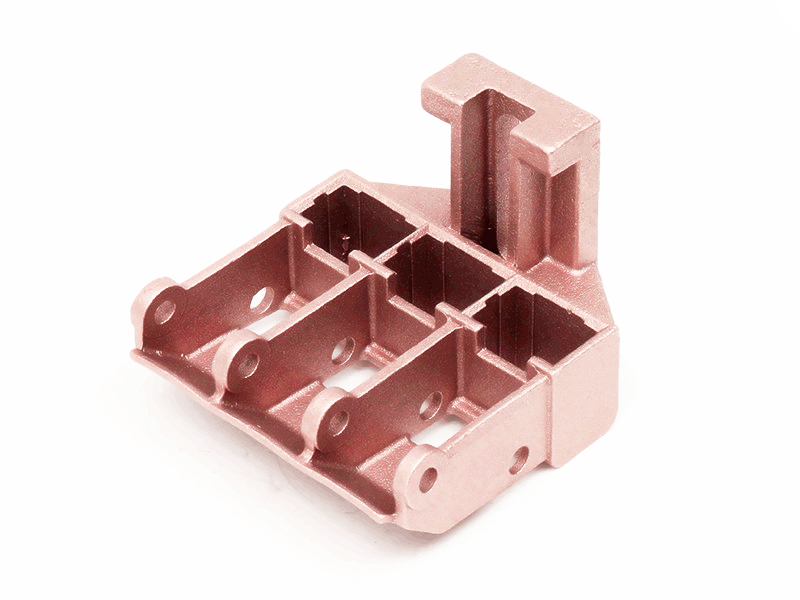

High-Precision Copper Die Casting for Durable Electrical Connectors and Terminals

Electrical systems rely on high-performance connectors and terminals to maintain consistent conductivity, mechanical integrity, and environmental durability. From industrial switchgear and vehicle harnesses to power distribution units and smart grid equipment, connector components must perform reliably under continuous current flow and physical stress. Copper die casting, particularly with specialized copper alloys, offers the ideal manufacturing method for producing these critical components at scale, with superior thermal and electrical conductivity, mechanical strength, and dimensional precision.

At Neway, we provide copper die casting services tailored for complex connector and terminal designs. Using advanced casting processes and high-conductivity copper alloys, we deliver tight-tolerance parts that meet the performance demands of modern power and signal systems.

Why Choose Copper Die Casting for Electrical Components

Copper’s outstanding electrical conductivity (~58 MS/m), thermal performance, and corrosion resistance make it a natural fit for electrical applications. Unlike copper forging or machining, high-pressure die casting enables complex shapes, embedded inserts, and rapid part production with tight repeatability.

Key Advantages

Electrical conductivity: up to 93% IACS for high-conductivity copper alloys

Tensile strength: 210–340 MPa depending on alloy selection

Dimensional tolerance: ±0.02 mm on precision contact points

High temperature endurance: continuous service at 150–200°C

Density of ~8.9 g/cm³ provides mechanical robustness and contact stability

Copper die casting allows integrated features such as threaded ports, mounting tabs, multi-branch terminals, and insulation barriers—all produced in a single cycle.

Common Applications in Electrical Connectors and Terminals

Copper die cast components are widely used in energy, transportation, infrastructure, and industrial automation systems.

Component Type | Application Examples | Key Functional Requirements |

|---|---|---|

Terminal Lugs | Power buses, battery connectors, inverter feeds | Low resistance, mechanical fatigue strength, corrosion resistance |

Plug Contacts | Smart meters, EV chargers, switchgear modules | Tight fit, oxidation resistance, dimensional accuracy |

Busbar Nodes | Panelboards, transformers, PDU enclosures | Thermal dissipation, high ampacity, mounting integrity |

Grounding Terminals | Control boxes, enclosures, cable trays | High surface conductivity, bolt pull resistance |

Multi-port Connectors | Cable adapters, connector headers | Complex geometry, sealing surfaces, repeatable dimensions |

Copper Alloys for Die Casting Connectors

Neway utilizes high-performance copper alloys that balance conductivity, castability, and strength. All alloys meet ASTM B148 and ISO 1634-1 electrical and mechanical component production standards.

Alloy | Electrical Conductivity (% IACS) | Tensile Strength (MPa) | Application Suitability |

|---|---|---|---|

C18200 | 80–85 | ~340 | High-load terminals, plug connectors, arc contacts |

C17500 | 50–60 | ~600 (after aging) | Spring-loaded contacts, high-stress terminals |

CuZn40 | 28–30 | ~320 | General-purpose connectors, good corrosion resistance |

CuNi10Fe1 | ~10 | ~400 | Marine-grade or harsh-environment electrical parts |

C18200 (chromium copper) is often the preferred choice for high-ampacity applications requiring both conductivity and wear resistance under thermal cycling.

Tolerancing and Surface Integrity

Electrical connectors demand tight control over fit, surface finish, and insertion/removal forces. Neway maintains high precision across high-volume copper die casting batches.

Wall thickness: 1.0–3.5 mm

Contact surface flatness: ≤ 0.03 mm

Tolerance on mating features: ±0.02 mm

Surface roughness: Ra ≤ 1.6 µm, post-processed

Porosity control: <0.5% using vacuum degassing and X-ray inspection

We offer CNC post-machining for high-voltage terminals and critical mounting holes to ensure alignment and tight press-fit tolerances.

Surface Treatments for Conductivity and Corrosion Resistance

Electrical terminals require low-resistance surfaces and protection against oxidation, especially in outdoor or high-humidity installations. Neway offers several post-processing and coating options:

Electroplating: silver, tin, or nickel plating for high-conductivity, oxidation-resistant contact areas

Powder coating: insulative and protective coatings for housing areas (60–100 µm)

Painting: color identification for phase marking or functional grouping

Tumbling and polishing: for smooth edge profiles and insertion-friendly finishes

Assembly: integration of threads, fasteners, O-rings, and insulation elements

All finishes meet RoHS, UL 94, and relevant IEC electrical standards where applicable.

Tooling and Production Capabilities

Neway’s tool and die making supports complex geometries and multi-cavity tools optimized for connector production.

Tool steel: H13 with surface-treated inserts for copper wear resistance

Die life: 100,000–300,000 shots for copper alloys

Part size: up to 250 mm for connector blocks, as small as 10 mm for pin contacts

Lead time: 4–6 weeks, including DFM and mold flow simulation

Production rate: 25–40 seconds per shot, depending on part geometry

Rapid prototyping available for functional testing of interface points and electroplating performance

Our low-volume and mass production services enable everything from early pilot runs to full OEM-scale supply programs.

Case Study: Busbar Terminal Block for Electrical Distribution Cabinet

A power distribution client required a multi-port connector block with the following specifications:

Rated current: 200 A

Terminal contact flatness ≤ 0.04 mm

Plating: 8 µm silver for all mating surfaces

Corrosion resistance: 500 hours salt spray

Operating temperature: up to 180°C

Annual volume: 150,000 units

Neway selected C18200 copper alloy, using a 3-cavity H13 tool design and built-in side cores to cast the mounting feet and tap-through hole features. Post-casting, the part was polished, CNC machined, and silver electroplated. All units passed current-carrying, torque load, and environmental tests with a first-pass yield of over 98.7%.

Why Electrical OEMs Choose Neway

Neway supports global power and electronics manufacturers with precision-engineered copper connector solutions:

In-house alloy selection, tooling, casting, and finishing

ISO 9001:2015-certified systems with full quality documentation

Support for UL/IEC compliance and PPAP documentation

Integration of CNC, coating, and assembly in a single workflow

Global delivery capabilities and technical collaboration

Neway delivers reliable electrical contact solutions, whether you’re developing a connector for EV platforms, switchboards, or industrial automation.

Conclusion

Copper die casting provides the precision, conductivity, and strength needed for today’s electrical connector and terminal designs. Complex geometry capability, tight tolerances, and proven finishing options enable the scalable production of high-quality electrical components. At Neway, we combine material science, advanced tooling, and controlled processes to deliver connector parts that meet the most demanding electrical and mechanical specifications.

To get started on your next high-precision copper casting project, contact Neway today.