Estimación de precios de anodizado: factores que influyen en el costo industrial

Introducción: ¿Por qué las cotizaciones de anodizado son tan diferentes?

Como ingeniero de acabado superficial en Newway, a menudo recibo esta pregunta de los clientes: “¿Por qué las cotizaciones para anodizar piezas similares pueden diferir varias veces?” La respuesta radica en la complejidad de los costos del anodizado. En la realidad, el anodizado nunca ha sido un proceso simple cuyo precio se calcule solo por peso. Su estructura de costos está impulsada por múltiples dimensiones, desde las características del material hasta los requisitos del proceso. Comprender estos factores de influencia no solo le ayuda a estimar con precisión los presupuestos del proyecto, sino que también permite optimizar costos mediante una comunicación eficaz con su proveedor.

Factor clave 1: Tamaño de la pieza y complejidad geométrica

Área superficial: la medida directa del costo

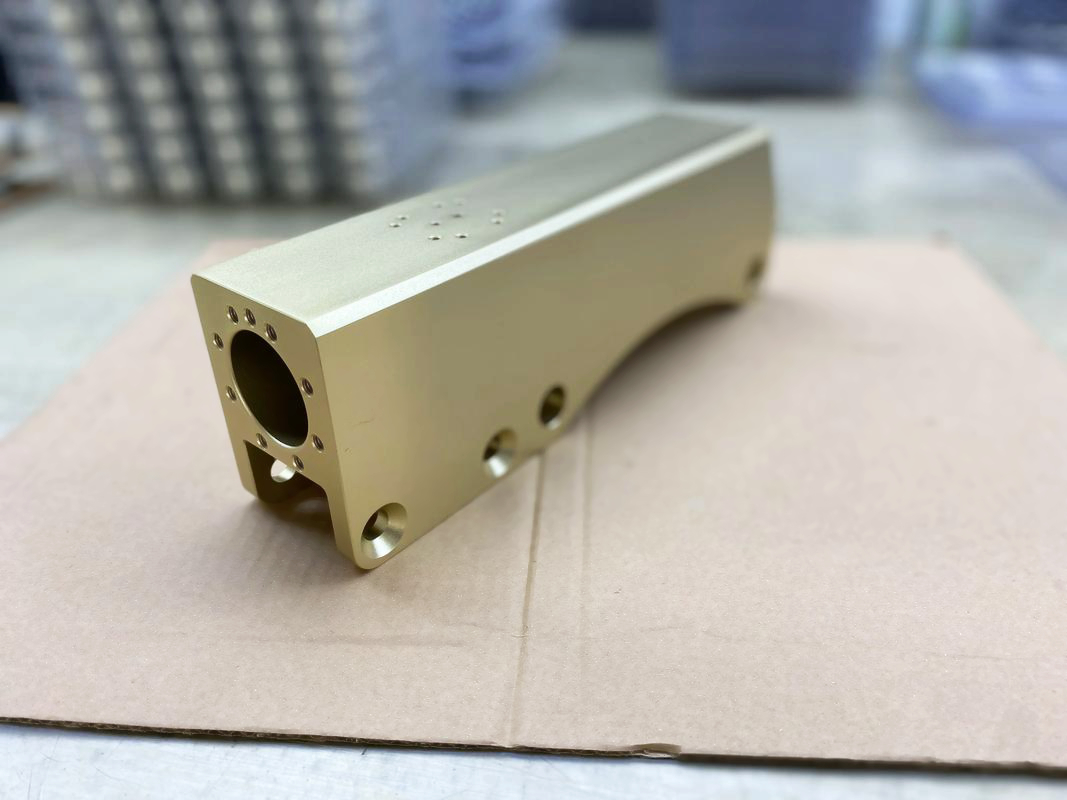

En los cálculos de costos de anodizado, el área total de superficie tratada es la unidad de precio más fundamental. El consumo de electrolito, el uso de químicos y la demanda de energía están directamente relacionados con el área superficial. Los clientes a menudo proporcionan el peso de la pieza para la cotización, pero en realidad, dos piezas con el mismo peso pueden diferir significativamente en área superficial debido a su diseño estructural. Un análisis preciso del modelo 3D es esencial para una cotización exacta, por eso recomendamos considerar el costo del proceso durante la etapa de servicios de diseño de fundición a presión.

El impacto de la geometría en el tiempo de procesamiento

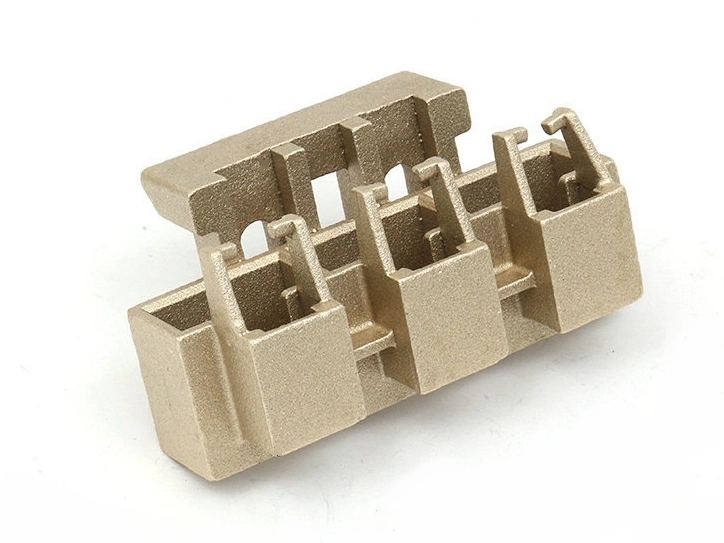

Las geometrías complejas son el “impulsor oculto” del aumento de costos. Orificios profundos, ranuras ciegas y cavidades internas requieren sujeción especial y ciclos de procesamiento más largos. Por ejemplo, una pieza con agujeros ciegos profundos necesitará pasos adicionales de limpieza y drenaje, lo que incrementa la mano de obra y el tiempo de ocupación del equipo. Las estructuras altamente complejas también pueden requerir bastidores o fixtures personalizados, y estas inversiones iniciales inevitablemente se reflejarán en la cotización final.

Factor clave 2: Tipo y espesor de la película anódica

Anodizado decorativo (Tipo II) vs. anodizado duro (Tipo III)

Los distintos tipos de anodizado difieren significativamente en costo. En nuestros servicios de anodizado estándar, el anodizado decorativo Tipo II generalmente se sitúa en el extremo inferior del rango de costos, mientras que el anodizado duro Tipo III—debido a mayor consumo de energía, mayor tiempo de proceso y un control de proceso más estricto—puede ser entre 50% y 200% más caro. El anodizado duro debe realizarse a temperaturas cercanas a la congelación, lo que requiere un importante gasto de refrigeración, y su ciclo de producción suele ser de dos a tres veces más largo que el anodizado convencional.

Requisitos de espesor: incrementos de costo a nivel de micras

El espesor de la película y el costo están correlacionados positivamente, pero no de forma lineal. El aumento de costo de 5 μm a 10 μm es mucho menos dramático que de 25 μm a 30 μm. A medida que aumenta el espesor, el consumo de energía se incrementa de manera desproporcionada y la eficiencia de producción disminuye. En casos extremos, lograr recubrimientos ultra gruesos que superen los 50 μm puede requerir múltiples ciclos de anodizado, lo que eleva significativamente el costo.

Factor clave 3: Tipo de aleación base de aluminio

El efecto del contenido de silicio

La composición de la aleación del sustrato afecta directamente la complejidad del proceso y el costo. Las aleaciones de aluminio con alto contenido de silicio, como A380, tienden a producir superficies gris mate después del anodizado. Lograr un acabado visualmente atractivo requiere electropulido adicional y ciclos de pretratamiento más largos, lo que incrementa el costo total. El silicio también afecta la uniformidad del teñido, lo que sugiere que podrían ser necesarios materiales base de mayor calidad para productos críticos en color.

Ventajas de las aleaciones de aluminio forjado

En contraste, las aleaciones de aluminio forjado como 6061 y 5052 tienen microestructuras más uniformes, lo que les permite formar películas anódicas de alta calidad y uniformes. Los costos de procesamiento son relativamente menores y los rendimientos son más altos. Equilibrar la maquinabilidad con el desempeño en tratamiento superficial al seleccionar materiales suele conducir al mejor resultado económico global.

Factor clave 4: Color y proceso de teñido

Natural vs. teñido

El anodizado natural (plateado) es la solución más económica, ya que omite el teñido y los pasos asociados de control de calidad. Cualquier proceso de teñido aumenta el consumo de químicos y el tiempo de procesamiento. El negro suele ser el tinte más rentable, mientras que ciertos colores especiales pueden depender de tintes orgánicos más costosos.

Colores estándar vs. colores personalizados

Los colores estándar ofrecen la mejor eficiencia de costos porque los proveedores pueden optimizar los procesos y comprar tintes a granel. Los colores personalizados requieren trabajo específico de igualación de color, incluidas pruebas de muestra y ajustes de parámetros, y estos costos de desarrollo suelen amortizarse en los precios unitarios. Para proyectos de fabricación de bajo volumen, el desarrollo de color personalizado puede representar una parte sustancial del costo total.

Anodizado secundario / enmascarado

Cuando las piezas requieren protección localizada o múltiples colores, se vuelve necesario el enmascarado y el anodizado selectivo. Este proceso implica pasos repetidos de enmascarado, anodizado y desmascarado, lo que incrementa la mano de obra y el tiempo de procesamiento. Los patrones complejos también pueden requerir fixtures dedicados, aumentando aún más los costos.

Factor clave 5: Cantidad y escala de producción

Costo unitario para lotes pequeños

En corridas de lotes pequeños, los costos fijos de preparación de equipos, diseño de colgado (racking) e inspección se reparten entre pocas piezas, resultando en precios unitarios más altos. Esta es una realidad común para los clientes durante las etapas de prototipo. Al planificar tamaños de lote y frecuencia de producción de forma más estratégica, los costos de lotes pequeños pueden optimizarse parcialmente.

Economías de escala

La producción de alto volumen reduce significativamente el costo unitario. Cuanto mayor es la cantidad, más delgada es la asignación de costos fijos. Al mismo tiempo, los proveedores pueden optimizar mejor los parámetros del proceso, el abastecimiento de materiales y la programación de producción. Los pedidos de decenas de miles normalmente obtienen los precios más competitivos.

Factor clave 6: Requisitos de postratamiento y acabado

Proceso de sellado

El sellado es un paso esencial después del anodizado, y los diferentes métodos de sellado varían significativamente en costo. El sellado en agua caliente tiene un costo químico relativamente bajo pero un alto consumo de energía; el sellado en frío, por otro lado, utiliza químicos más caros pero ahorra energía. Para aplicaciones específicas, como perfiles arquitectónicos, puede seleccionarse un sellado a temperatura media para equilibrar desempeño y costo.

Condición superficial inicial antes del anodizado

La condición superficial previa al anodizado influye directamente tanto en la calidad como en el costo. El arenado puede crear una textura mate uniforme, pero añade pasos adicionales. Las piezas de alto brillo pueden requerir mecanizado CNC o pulido mecánico. Todo post-mecanizado para piezas fundidas a presión incrementa la base de costo total.

Tratamientos especiales después del anodizado

El desbarbado posterior al anodizado, el pulido o requisitos especiales de empaque son operaciones adicionales. Cada paso añadido consume capacidad extra de equipo, mano de obra y recursos de control de calidad. Definir claramente estos requisitos en la etapa de RFQ ayuda a asegurar estimaciones precisas del costo total.

Factor clave 7: Aseguramiento de calidad y estándares industriales

Niveles de inspección

El alcance de inspección para piezas de grado comercial difiere sustancialmente del de piezas industriales o críticas para misión. Las aplicaciones médicas o aeroespaciales pueden requerir verificaciones por lote del espesor de la película, pruebas de adhesión y ensayos de niebla salina. Estos procesos estrictos de QA pueden añadir entre 15% y 30% al costo. El cumplimiento de MIL-A-8625 y estándares similares también exige mayores frecuencias de prueba y registros más completos.

Certificaciones y documentación

Proporcionar certificados de material, certificaciones de proceso e informes de inspección por lote implica un esfuerzo administrativo y de gestión considerable. Para productos que requieren trazabilidad completa, son esenciales controles de lote robustos y sistemas de documentación, y estos costos ocultos se reflejan naturalmente en la cotización.

Cómo obtener cotizaciones precisas y colaborar eficazmente con Newway

Lista de información clave para proveedores

Para recibir una cotización precisa, por favor proporcione: planos 3D completos (con dimensiones críticas marcadas), grado y temple de la aleación, espesor de película requerido y normas aplicables, especificación de color (Pantone o muestra), cantidad estimada, criterios de aceptación y cualquier requisito especial. Cuanta más completa sea la información, más exacta y transparente será la cotización.

Precios transparentes de Newway y servicios de valor añadido

En Newway, nos apoyamos en el análisis de ingeniería para piezas fundidas a presión para ayudar a los clientes a optimizar costos desde el diseño hasta la producción. Nuestro modelo de servicio integral integra fundición a presión, mecanizado y tratamiento superficial, eliminando la necesidad de proveedores intermedios y simplificando la logística para ofrecer costos totales más competitivos.

Conclusión: invierta en valor, no solo en precio

Los costos del anodizado son el resultado de múltiples factores que interactúan. Los responsables de decisión inteligentes se enfocan en el costo total de propiedad en lugar de comparar únicamente precios unitarios. Al asociarse con proveedores experimentados y técnicamente capaces como Newway, obtiene no solo estimaciones precisas de costos, sino también ahorros a largo plazo mediante la optimización del proceso. Trabajemos juntos para encontrar el equilibrio óptimo entre eficiencia de costos y calidad del producto.

FAQ

¿Por qué el precio unitario del anodizado en lotes pequeños (dentro de 100 piezas) es tan alto?

¿Puedo enviar muestras para un anodizado de prueba y una evaluación de cotización primero?

¿Cómo afecta al precio exceder el espesor de película anódica especificado?

¿Newway ofrece cotizaciones integradas que incluyan pasos de pretratamiento y postratamiento?