Shot Peening: How This Process Extends the Life of Die Casting Tools and Dies

Introduction

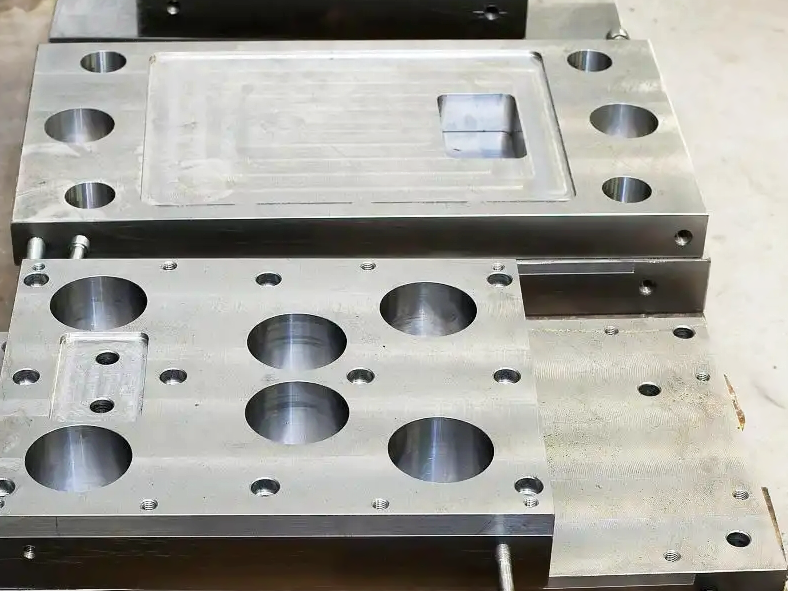

Die casting tools and dies endure repeated thermal shocks, high injection pressures, and mechanical wear during mass production. Over time, these stresses lead to surface fatigue, microcracks, and eventual tool failure. Shot peening is a widely adopted mechanical surface treatment that strengthens die surfaces by inducing beneficial compressive stresses. Used across aerospace, automotive, and metal forming industries, shot peening is particularly valuable for increasing the life expectancy of H13 steel, D2 steel, and P20 steel dies used in high-pressure and gravity die casting.

What Is Shot Peening?

Shot peening is a cold working process that bombards a metal surface with small spherical media (steel, ceramic, or glass) at high velocities. Each impact creates a microscopic indentation, causing plastic deformation and compressive residual stress in the outer layers of the material. Key process parameters include:

Media diameter: 0.2–1.0 mm

Impact velocity: 50–100 m/s

Coverage rate: 100–200% depending on application

Almen intensity: 0.008–0.024 A (for tool steels)

This compressive stress layer impedes crack formation and propagation, especially in thermal fatigue-prone die mold areas such as cavities, cores, and parting lines.

Key Benefits of Shot Peening in Die Casting

Benefit | Typical Improvement | Tooling Impact |

|---|---|---|

Fatigue Resistance | Up to 30% improvement | Extends tool life during thermal cycling |

Crack Suppression | Reduced surface tension | Delays initiation and propagation of microcracks |

Surface Stress Control | Residual stress up to -700 MPa | Improves structural integrity of high-load components |

Surface Conditioning | Removes minor surface defects | Prepares surfaces for coatings or plating |

Shot peening is often applied to aluminum, zinc, and copper alloy die tools that experience short cycle times and high thermal gradients.

Suitable Tool Steels and Applications

Shot peening best suits heat-treated die steels with high hardness and wear resistance. Common applications include:

H13 Steel Dies: Improves thermal fatigue resistance in aluminum alloy casting

D2 Steel Inserts: Reduces crack growth in wear-critical ejector pins and cores

P20 and S7 Tooling: Enhances durability in lower temperature or zinc die casting applications

The process is especially useful for dies in mass production, where minor fatigue failures can lead to expensive downtime and reworking.

Practical Application in Die Tool Maintenance

Shot peening is typically performed during initial tool preparation or as part of scheduled maintenance. It complements other surface treatments such as nitriding or PVD by enhancing base material integrity before coating application. In Neway’s die tool service workflow, shot peening is applied to:

Core pins and sleeves

Parting surfaces and cavity walls

Ejector plates and moving die segments

For example, shot-peened H13 core pins used in A380 casting maintained full functional integrity beyond 80,000 shots, compared to 50,000 in unpeened equivalents.

Integration with Post-Processing and Surface Finishing

Following shot peening, surface roughness may increase slightly (Ra +0.2–0.6 µm), which can be corrected by polishing or tumbling based on final surface finish requirements. In multi-step workflows, shot peening is typically performed before nitriding, coating, or electroplating to ensure strong adhesion and improved layer performance.

Routine re-peening is incorporated into preventive maintenance plans for tools used in aggressive casting environments, extending their operational lifespan and improving tooling ROI.

FAQs

How does shot peening improve thermal fatigue resistance in die casting tools?

What tool steel grades benefit most from shot peening?

Can shot peening be combined with other surface treatments like PVD or nitriding?

What is the ideal peening intensity for die steel inserts?

Does shot peening affect tool dimensional tolerances?