Durable Zamak Die Cast Lock Mechanisms for Security and Hardware Applications

In locks and security hardware, durability, tamper resistance, and precise fit are essential to guarantee long-term functionality and user safety. Whether used in door locks, padlocks, safes, tool cabinets, or mailboxes, the internal mechanisms must operate flawlessly under mechanical stress, environmental exposure, and repetitive use. Zamak die casting offers a robust, economical, and scalable solution for manufacturing complex lock housings, cams, tumblers, and latch components with excellent strength and surface integrity.

At Neway, we specialize in zinc alloy die casting using premium Zamak grades such as Zamak 3, Zamak 5, and Zamak 2. Our components meet the exact tolerances and performance requirements demanded by global lock and security hardware OEMs.

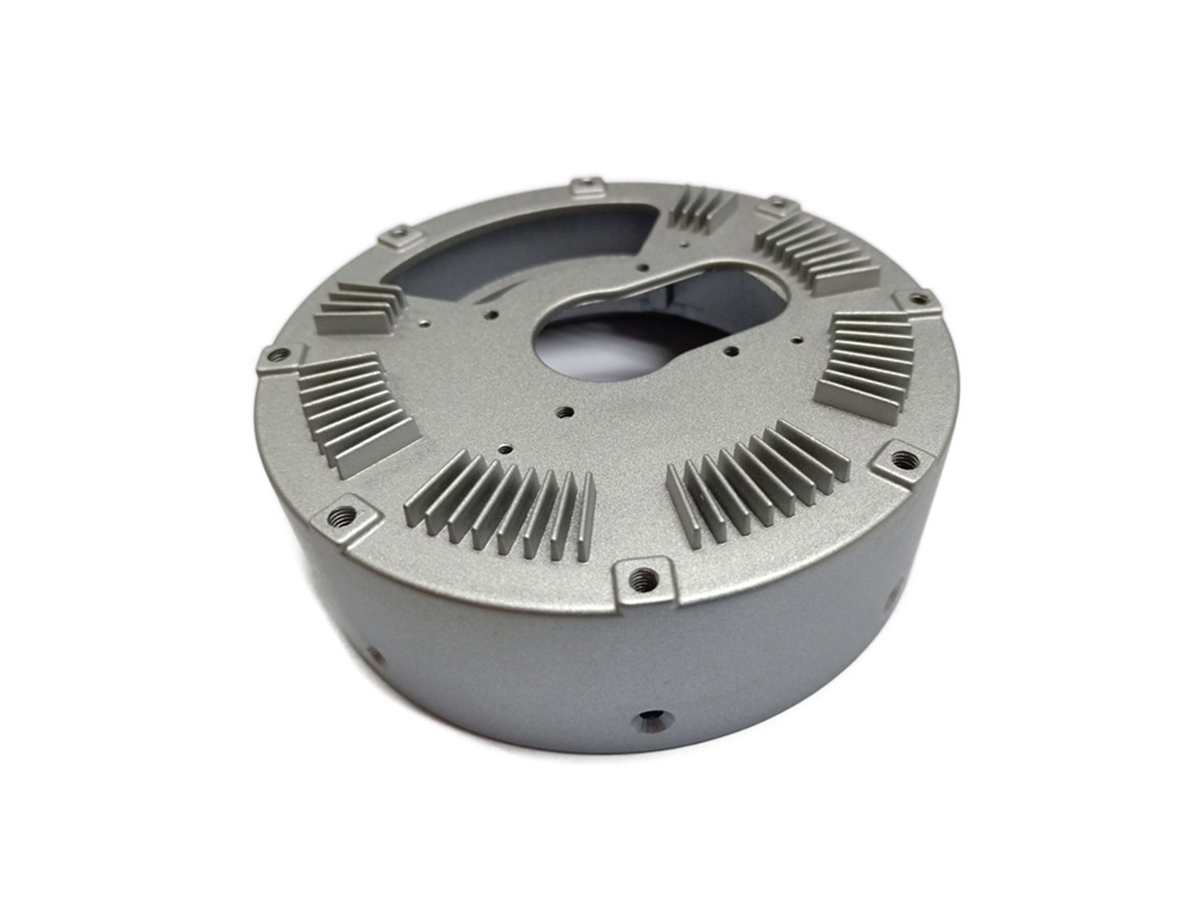

Why Zamak Die Casting is Ideal for Locking Mechanisms

Zamak (zinc-aluminum-magnesium-copper) alloys are ideal for lock mechanisms due to their strength, fluidity, and dimensional stability. High-pressure die casting enables intricate parts to be formed in a single cycle, with minimal machining, tight tolerances, and repeatable results across high volumes.

Key Advantages

Tensile strength reaches 400 MPa (Zamak 5), making it ideal for load-bearing and wear-resistant parts. Casting tolerances are held at ±0.02 mm for mating shafts, pins, and tumblers. Wall thickness can go as low as 0.8 mm, and surfaces can achieve Ra ≤ 1.6 µm via tumbling or sand blasting. Enhanced corrosion resistance of more than 500 hours in salt spray (ASTM B117) is possible with powder coating or electroplating.

Applications of Die Cast Lock Components

Zamak die casting supports various mechanical locking systems and security hardware components.

Component Type | Application Examples | Key Functional Requirements |

|---|---|---|

Lock Housings | Mortise locks, cylinder locks, padlocks | Structural integrity, tamper resistance, corrosion resistance |

Rotating Cams | Mailbox locks, cabinet locks, vending locks | Smooth rotation, wear resistance, fit consistency |

Tumblers and Sliders | Combination locks, file cabinet locks | Precision tolerances, dimensional repeatability |

Latches and Bolts | Safe locks, toolbox locks, gun cabinet locks | Load-bearing strength, tolerance to impact and fatigue |

These components often feature integrated bosses, slots, notches, and undercuts—efficiently achieved through high-pressure Zamak casting.

Zamak Alloys for Security and Hardware Applications

Neway offers several Zamak alloy options that conform to ASTM B86 and ISO 301 standards for strength, castability, and surface performance.

Alloy | Tensile Strength (MPa) | Elongation (%) | Best Use Case |

|---|---|---|---|

Zamak 3 | 270–280 | ~10 | Standard lock housings and cosmetic components |

Zamak 5 | 380–400 | ~7 | Load-bearing parts with added strength |

Zamak 2 | 410–425 | ~3 | High-strength lock cams and structural internals |

Zamak 2 is the most suitable for highly stressed components like bolts and rotating cams, where rigidity is paramount.

Precision and Functional Tolerances

Precision is critical in lock assemblies for smooth operation and long-term reliability.

Dimensional tolerance is controlled to ±0.02 mm for components such as tumblers and shafts. Flatness is maintained at ≤ 0.05 mm on key mating surfaces. Hole position accuracy is held to ±0.03 mm, and surface roughness can be reduced to Ra ≤ 1.2 µm. Porosity is controlled to <0.5% and validated by vacuum or X-ray inspection.

Surface Treatments and Corrosion Protection

Security hardware components require excellent durability against environmental wear. Neway offers robust post-processing solutions:

Electroplating: chrome, nickel, and black chrome compliant with ISO 9227

Powder coating: coatings up to 100 µm thick for abrasion and UV protection

Painting: color coding and brand-matching per RAL or Pantone

Assembly: includes installation of springs, push rods, and fasteners

All finishes meet RoHS, REACH, and applicable hardware durability standards.

Tooling, Prototyping, and High-Volume Production

Neway’s tool and die making capabilities support pilot projects and long-term production runs.

Die steel is based on H13, with tool life ranging from 250,000 to 500,000 cycles. Tooling lead time is typically 4–6 weeks. Part cycle times are between 25 and 40 seconds, depending on geometry. Rapid prototyping is available using 3D-printed or soft steel dies.

We support low-volume and mass production requirements with full in-house process control.

Case Study: Industrial Cam Lock System

A security hardware client required a corrosion-resistant lock mechanism for use in industrial enclosures. Specifications included:

Torque resistance > 500 N

Corrosion resistance: >800 hours salt spray (ASTM B117)

Flatness ≤ 0.05 mm across 90 mm bracket interface

Plated surface hardness > 5H (pencil test)

50,000+ cycle durability

Neway recommended Zamak 5 for housings and Zamak 2 for internal cams. A 3-cavity die system was used, with post-process electroplating and assembly. The program achieved 98.8% first-pass yield with full traceability.

Why Security OEMs Trust Neway

Neway is a trusted supplier to global lock and hardware brands for:

Complete engineering support from concept through production

ISO 9001:2015 certified quality and testing systems

Tooling strategies tailored for complex multi-cavity dies

Batch-level traceability with inspection data logging

Full service logistics for JIT and international shipments

We supply lock bodies, tumblers, cams, and latches that meet security and performance benchmarks across global markets.

Conclusion

Zamak die casting is a proven, cost-effective method for manufacturing high-strength, high-precision components in lock mechanisms and hardware assemblies. At Neway, we combine advanced tooling, process control, and finishing to deliver secure, consistent, and scalable locking solutions for OEMs and suppliers worldwide.

To start your custom security hardware project, contact Neway today.