Guide to Accurately Calculating Metal Casting Project Costs

Introduction

Accurate cost estimation is critical for the success of any metal casting project. From prototype development to mass production, understanding the true cost structure enables manufacturers to make informed decisions, optimize designs, and maintain profitability. Yet, with so many variables—tooling, materials, processes, post-processing, and market factors—cost calculation can quickly become complex.

This guide provides a systematic, engineering-based approach to calculating metal casting project costs. It will help manufacturers, buyers, and project managers identify key cost drivers, apply reliable estimation methods, and improve cost control throughout the entire project lifecycle.

Key Cost Components in Metal Casting Projects

Key Cost Components in Metal Casting Projects

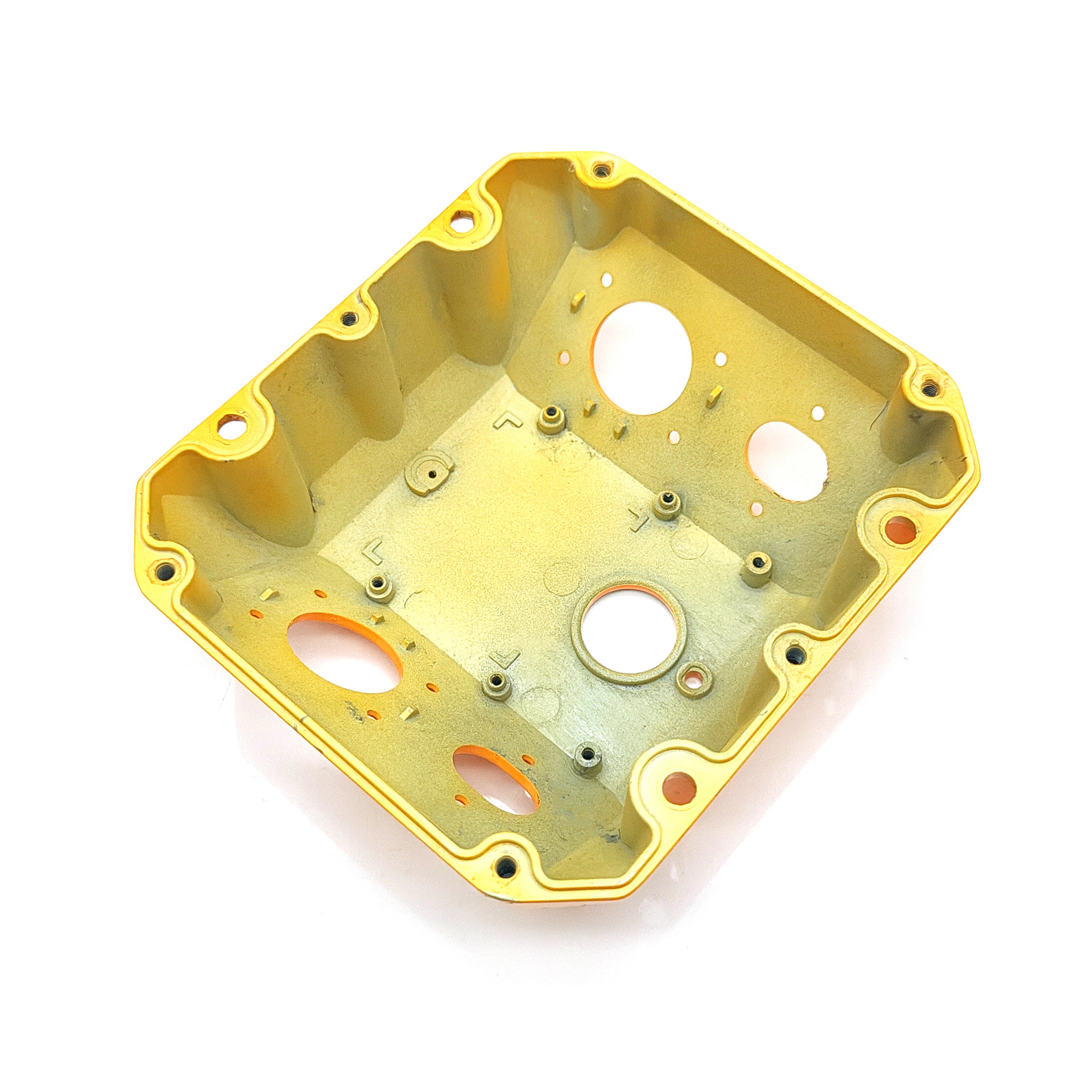

To accurately calculate the cost of a metal casting project, it is essential to understand the core cost components. Each element—tooling, materials, processing, and finishing—contributes to the overall budget and must be carefully analyzed during project planning. This section breaks down these key cost drivers.

Tooling and Pattern Costs

Tooling costs are often the largest upfront investment in metal casting.

High-pressure die casting (HPDC) requires highly engineered steel molds that can cost from $20,000 to over $100,000, depending on part complexity, size, and expected production volume.

Gravity casting uses more affordable permanent molds, while sand casting requires lower-cost patterns made from wood, resin, or metal.

Tooling cost is influenced by:

Part geometry (thin walls, undercuts, internal cavities)

Surface finish requirements

Mold material and life expectancy

Production volume (tools designed for high volumes are more robust but costlier)

It is critical to amortize tooling costs over projected production volume to determine the true per-part cost.

Material Costs

Raw material cost is another major factor in casting project economics.

The price of metals such as aluminum alloys, zinc alloys, or copper alloys fluctuates based on market conditions and alloy type.

Material utilization is also critical: casting produces near-net shape parts, but gating, risers, and trimming result in some unavoidable waste.

To estimate material cost:

Calculate the net part weight based on a 3D model.

Add typical process-specific yield loss (e.g., 5–15% for HPDC, 10–20% for gravity or sand casting).

Multiply by the current alloy price per kilogram.

Using recycled materials where appropriate can further improve material cost efficiency.

Process Costs (Melting, Casting, Finishing)

Process costs encompass labor, energy, equipment depreciation, and indirect overhead. Key considerations include:

Melting energy costs: Higher for alloys with elevated melting points (e.g., copper alloys).

Casting cycle time: HPDC offers short cycles (seconds), while sand casting and investment casting require longer cycles (hours to days).

Labor intensity varies by process—manual operations in sand casting increase cost compared to automated HPDC cells.

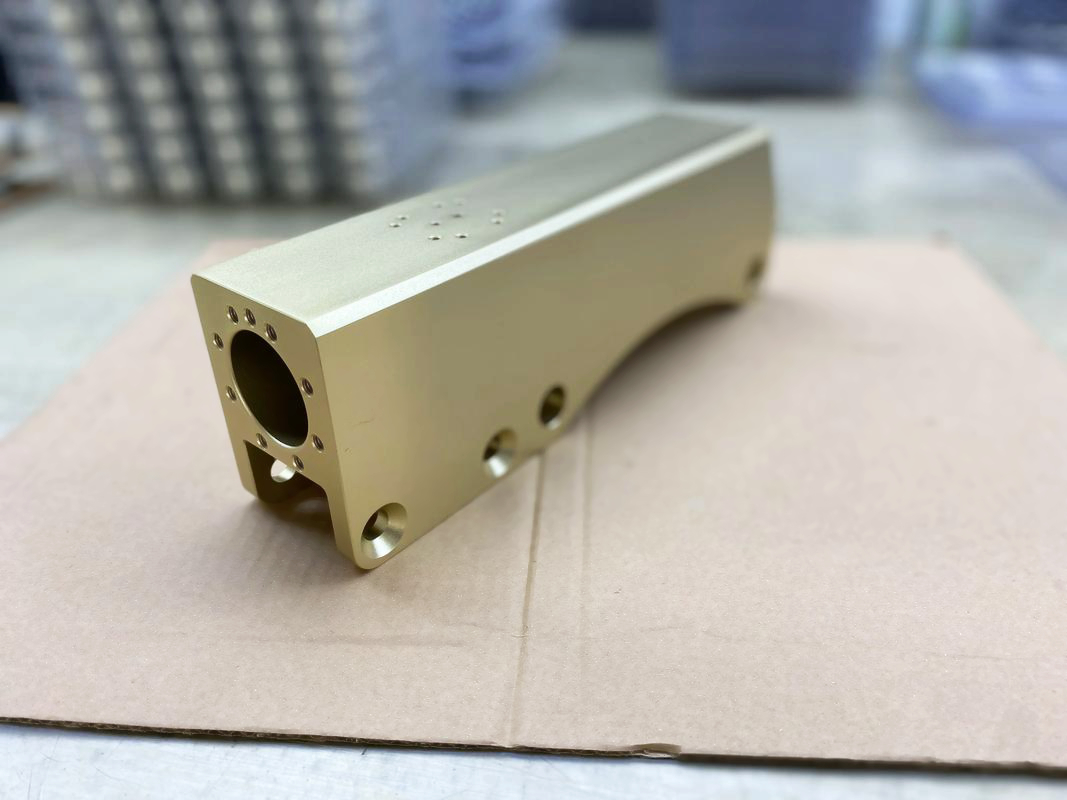

Post-processing also represents a significant portion of casting cost:

Post-machining is often required to meet tolerance and surface finish requirements.

Additional surface treatments—such as anodizing, powder coating, or painting—enhance corrosion resistance and aesthetics.

For high-end applications, premium surface finishes add further value but increase cost.

Finally, inspection and quality assurance—such as CMM measurement or X-ray for internal defects—should be included in cost estimates, especially for critical components.

Factors Affecting Overall Casting Cost Accuracy

Achieving accurate cost estimates for metal casting projects requires a thorough understanding of the variables that can introduce cost variability. The following factors can significantly influence cost accuracy—neglecting them can lead to underestimations or unexpected overruns.

Production Volume and Economies of Scale

Production volume is one of the most influential factors in casting cost optimization.

For low-volume manufacturing or prototype runs, the tooling cost forms a large proportion of the per-part cost. CNC machining or sand casting may be more economical in such cases.

As volume increases, fixed tooling costs are amortized over a greater number of parts, driving per-part cost down significantly in high-pressure die casting (HPDC) or gravity casting.

Understanding these scale effects is key to selecting the right process and accurately modeling project cost over its lifecycle.

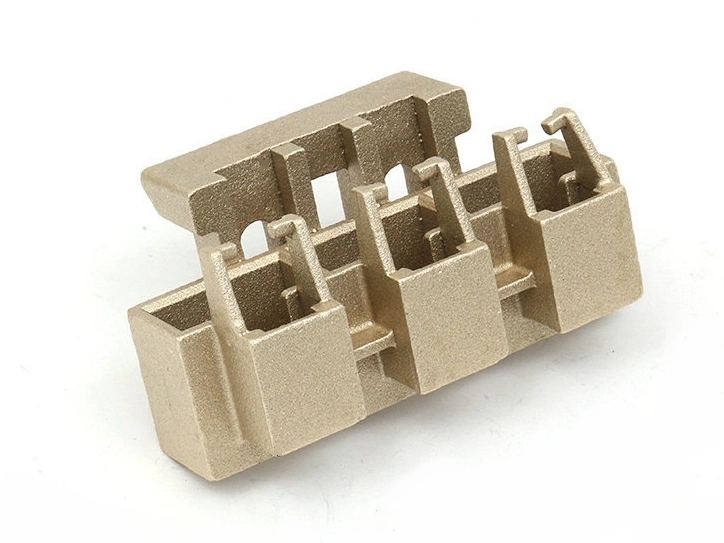

Part Geometry and Complexity

Part complexity directly affects:

Tooling cost: intricate designs require complex molds with more cores, slides, or moving parts.

Cycle time: Complex shapes often require slower fill rates, controlled cooling, or longer solidification.

Secondary operations: thin walls, deep pockets, or fine features may necessitate more extensive post-machining or surface treatments.

Failing to account for complexity-driven costs can result in substantial budget discrepancies, especially for precision components like consumer electronics housings.

Tolerance and Quality Requirements

Tight tolerances and stringent quality standards drive additional costs:

Achieving tolerances below ±0.1 mm often requires post-machining even on HPDC parts.

Complex surface finishes (such as anodizing or powder coating) must be budgeted separately.

High-value sectors such as aerospace or medical devices demand comprehensive quality assurance, including CMM, X-ray inspection, or CT scanning.

Quality-related costs include not only inspection but also scrap rates and potential rework, critical to include in a realistic TCO analysis.

Supply Chain and Lead Time Considerations

External market factors can introduce cost variability:

Raw material pricing: The cost of aluminum alloys, zinc alloys, or copper alloys is subject to global commodity trends and should be updated frequently during project planning.

Logistics: Complex supply chains may require buffer stock or expedited freight, both of which impact project costs.

Lead times: Tight schedules may necessitate expedited tooling production or overtime labor, which should be accounted for in estimates under an expedited fee or premium pricing model.

By modeling these factors systematically, engineers and procurement teams can greatly improve the accuracy of casting project cost forecasts.

Cost Estimation Process: Step-by-Step Guide

A structured cost estimation process helps ensure that all variables are captured and that the final cost projection is realistic and defensible. The following step-by-step guide provides a proven framework for accurately calculating metal casting project costs.

Define Project Scope and Requirements

Cost estimation begins with a clear definition of project parameters:

Production volume: prototype, low volume, or high volume

Material: aluminum alloys, zinc alloys, copper alloys, or specialty metals

Target tolerances: affect post-machining and inspection costs

Surface finish requirements: raw cast, anodized, powder coated, painted, etc.

Quality certification needs: e.g., CMM, X-ray inspection, PPAP, aerospace traceability

The more detailed the input, the more accurate the cost estimation.

Select an Appropriate Casting Process

Selecting the right process is crucial to both cost and technical success:

Sand casting: cost-effective for prototypes and large, simple parts

Gravity casting: good balance for mid-volume runs

High-pressure die casting (HPDC): ideal for high-volume, thin-walled, complex parts

Investment casting: for complex geometries with superior surface finish

Choice of process affects tooling costs, per-part cost, and achievable tolerances—so it must be made early in project planning.

Perform a Detailed Cost Breakdown

Each cost component should be estimated separately:

Tooling Cost

Quoted from the casting supplier based on part complexity and volume

Amortized across expected production volume

Material Cost

Net part weight + process-specific yield loss

Current alloy price per kg (spot pricing or contract pricing)

Process Cost

Melting energy, labor, and cycle time

Depreciation of casting equipment

Post-Processing Cost

Post-machining based on required tolerances

Surface treatment: anodizing, powder coating, painting

Finishing labor and material costs

Inspection and Quality Cost

Required dimensional inspection (manual, CMM)

Non-destructive testing (X-ray, CT scan)

Documentation and certification

Calculate Total Cost and Per-Part Cost

With all components detailed, calculate:

Total project cost = tooling + materials + processing + post-processing + inspection

Per-part cost = (total project cost - tooling) ÷ number of parts + (tooling amortization ÷ number of parts)

Additionally, perform a sensitivity analysis to assess how changes in volume or material prices would affect per-part cost.

Include Contingency and Risk Allowances

No estimate is perfect—it's good practice to add a contingency margin for uncertainties such as:

Material price fluctuations

Labor cost changes

Unexpected scrap or rework rates

Supplier delays or tooling maintenance issues

A typical contingency allowance is 5–15%, depending on project complexity and supply chain risk.

By following this structured approach, manufacturers can develop highly accurate, transparent cost estimates that support informed decision-making and competitive quoting.

Practical Tips for Improving Cost Accuracy and Control

Even with a structured estimation process, real-world projects can still face cost variances. The following best practices help manufacturers improve cost accuracy and maintain better control throughout the casting project lifecycle.

Engage with Experienced Casting Partners

Partnering with an expert foundry such as Neway Die Casting provides significant advantages:

Deep process knowledge to guide optimal process selection

Accurate tooling and production cost forecasting

Integrated services (casting, post-machining, surface treatment, and inspection) to reduce coordination overhead and improve cost predictability

An experienced supplier can also advise on material selection, design changes, and risk mitigation, helping avoid costly mistakes.

Leverage Design for Manufacturability (DFM)

DFM is one of the most effective levers for reducing casting costs:

Simplifying part geometry reduces tooling complexity and processing time

Reducing unnecessary tight tolerances lowers post-machining cost

Optimizing wall thicknesses improves material utilization and yield

Early collaboration between design engineers and casting experts enables DFM-driven cost optimization.

Utilize Advanced Simulation and Analysis

Modern simulation tools allow manufacturers to virtually optimize the casting process before tooling is cut:

Mold flow analysis predicts filling behavior, identifies potential defects, and helps refine gate design

Thermal analysis ensures proper cooling and solidification, reducing internal stress and porosity risks

Simulation reduces trial-and-error in tooling development, accelerating launch and minimizing costly rework.

Monitor and Review Costs Throughout the Project

Finally, continuous cost monitoring ensures that actual performance aligns with estimates:

Track material usage, scrap rates, cycle times, and rework costs in production

Periodically review supplier performance and validate process stability

Update cost models regularly to reflect actual learnings

Proactive cost management not only improves forecast accuracy but also drives continuous improvement, delivering sustained cost competitiveness across the project lifecycle.