Achieving Premium Surface Quality in Die Cast Components with CNC Finishing

Introduction

In high-performance applications, surface quality on die cast components is no longer just a cosmetic concern—it is directly tied to functional reliability, sealing performance, noise behavior, wear resistance, and perceived product value. While modern precision metal casting service can deliver excellent as-cast surfaces, premium applications typically require a combination of controlled casting, engineered post-processing, and high-accuracy CNC finishing to reach final specifications.

At Neway, we treat CNC finishing as a critical extension of the die casting process rather than an isolated step. By integrating tooling design, alloy selection, casting parameters, and structured machining routes, we help customers achieve consistent high-end surface quality on aluminum, zinc, and copper-based die castings, from consumer-grade housings to industrial and automotive structures.

Why Surface Quality Matters in Die Cast Components

Surface quality directly affects both the appearance and performance of die cast parts. For visible components in consumer electronics, power tools, or automotive interiors, surface defects translate into perceived lower quality—even when the underlying geometry is correct. For functional surfaces such as sealing faces, bearing seats, and sliding interfaces, roughness and waviness can lead to noise, leakage, accelerated wear, or unstable torque behavior.

Applications built on high-pressure aluminum die casting often combine lightweight structures with stringent flatness and surface finish targets. Zinc components used for intricate decorative hardware and mechanisms demand a stable base texture for plating or coating. Copper and brass alloys applied in thermal and electrical systems require controlled surfaces for stable contact resistance and heat transfer.

Starting from a Stable Casting Foundation

Premium surface quality begins with a controlled casting process. Defects such as cold shuts, misruns, excessive porosity, or poorly placed gates create conditions that no machining or polishing step can fully hide. That is why our engineers work closely with customers during the early design phase through dedicated engineering design for die castings.

We assess wall thickness, rib layout, draft angles, and overflow design to ensure that the initial geometry supports both casting integrity and subsequent finishing. For different alloy families, such as our aluminum die casting alloys portfolio, zinc die casting alloy options, and copper and brass casting alloys, we adjust gating and cooling strategies to minimize sink marks, surface porosity, and segregation that would compromise cosmetic or functional finishing.

The Role of CNC Finishing in Surface Quality

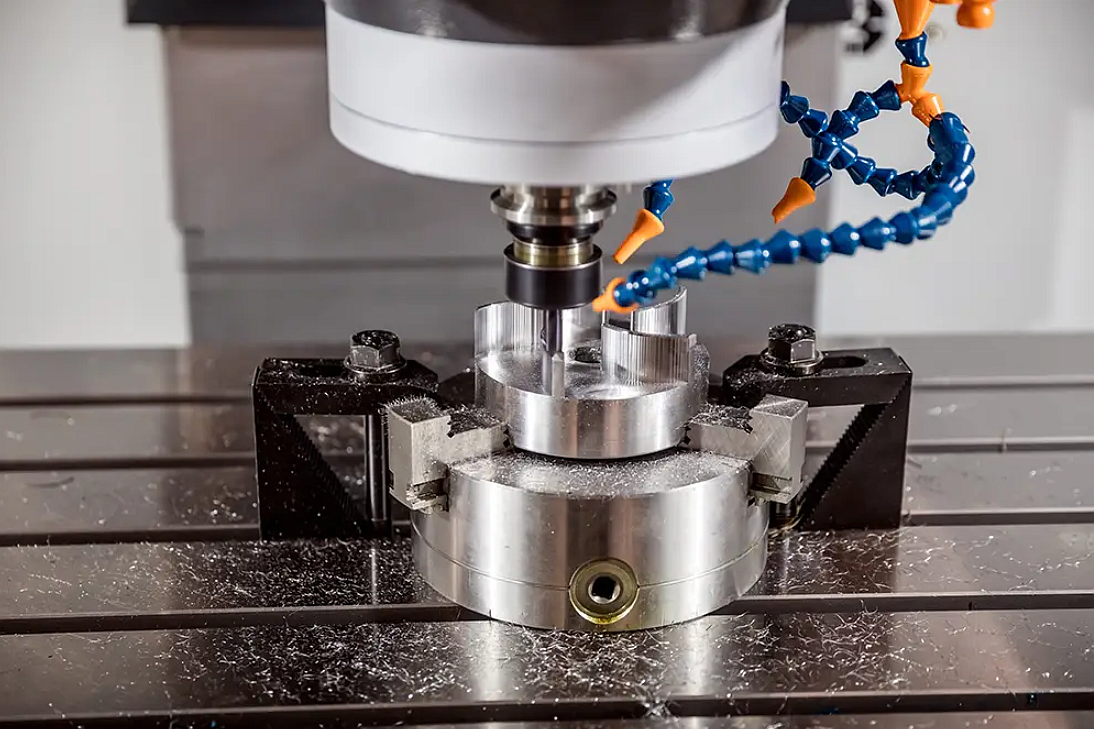

CNC finishing bridges the remaining gap between as-cast surfaces and final design targets. High-precision CNC machining services enable us to control not only dimensions and tolerances but also roughness, texture orientation, and local flatness on critical regions.

Typical CNC finishing tasks for premium surfaces include:

Planarization of sealing faces and mounting flanges

Finish boring of bearing seats and precision bores

Profiling of functional contours and sliding tracks

Fine milling of visible surfaces with defined tool paths

Chamfering and edge breaking for ergonomic and safety reasons

For demanding projects, CNC finishing is often combined with die castings post machining operations such as drilling, tapping, reaming, and fine contouring, forming a single integrated route that stabilizes both geometry and surface condition in one controlled workflow.

CNC Finishing Strategies for Different Alloys

Each alloy system behaves differently under machining, which means that cutting parameters, tool selection, and strategy must be tailored to the specific material.

For aluminum die castings, especially those used in projects similar to the A380 GPU frame reference design, we prioritize stable chip evacuation and thermal control to avoid built-up edge and micro-tearing on surfaces. Fine finishing passes with optimized speeds and feeds, combined with suitable tool coatings, enable the achievement of low Ra values and consistent reflectivity.

Zinc components, often produced through tight-tolerance precision zinc die casting, are more forgiving in terms of cutting forces but require careful control to avoid smearing or surface contamination that could impact plating or coating. We use sharp tools, moderate cutting speeds, and fine stepovers to generate clean, uniform textures suitable for decorative finishes.

Copper and brass die castings, produced through high-conductivity copper die casting, demand strategies that balance heat generation, tool wear, and edge sharpness. For contact surfaces in electrical or thermal systems, specific roughness ranges are selected to optimize real contact area without creating excessive friction or fretting.

Integrating CNC Finishing with Post-Process Steps

To achieve truly premium surfaces, CNC finishing must be coordinated with all other post-process steps. At Neway, we group these operations within a unified, integrated post-process for die castings, which can include deburring, cleaning, surface conditioning, and protective treatments.

Mass finishing steps, such as vibratory tumbling service and controlled sand blasting for die castings, help remove residual burrs, homogenize textures, and prepare large areas for coating. Meanwhile, CNC finishing focuses on critical zones where tolerances or local roughness must be tightly controlled.

For coated components, we coordinate CNC operations with:

liquid painting finishes for complex color and gloss requirements

durable powder coating line for robust corrosion resistance

aluminum anodizing treatment for wear and color stability

plasma arc anodizing technology for advanced protective layers

By carefully sequencing CNC finishing and coatings, we protect functional surfaces, prevent edge build-up, and ensure that both visual and dimensional requirements are met.

Designing for Premium CNC-Finished Surfaces

Achieving the desired surface quality economically is only possible when the component is designed with machining in mind. During joint reviews supported by our die casting prototyping support, we evaluate models for tool accessibility, fixturing feasibility, and unnecessary finishing areas.

Key design guidelines include:

Concentrating premium surfaces in accessible regions to avoid complex multi-axis strategies where not required

Defining realistic roughness ranges—focusing on ultra-smooth finishes only where they impact function or perceived value

Adapting rib and boss layouts to maintain rigidity during machining and prevent chatter marks

Providing sufficient machining allowance to remove casting skin while minimizing waste

In early development, we often combine rapid prototyping services with limited CNC finishing to validate not only form and fit but also the visual and tactile impact of surface grades before committing to final tooling.

Process Validation and Surface Inspection

Premium surface quality requires measurable, repeatable control. Neway’s finishing routes are validated and monitored with a combination of dimensional and surface-related metrics using our die casting inspection equipment.

Typical validation includes:

Measuring Ra, Rz, and waviness at critical locations across multiple samples

Verifying flatness and parallelism after CNC planarization

Performing coating adhesion and cross-hatch tests for finished surfaces

Running functional tests for sealing, torque, or sliding performance

Inspecting cosmetic zones under controlled lighting conditions

Once the finishing process is frozen, we maintain stability through SPC monitoring, tool life tracking, and periodic requalification. For complex programs, we also establish golden samples to align visual acceptance between Neway and the customer.

Scaling from Prototype to Mass Production

Surface quality expectations do not change when a project moves from prototype to series production—if anything, consistency becomes even more critical. We support this transition through low-volume manufacturing solutions that bridge the gap between early engineering builds and final ramp-up.

During this phase, we refine CNC toolpaths, optimize cycles, and validate fixture concepts. Once volumes scale up, the same finishing strategies are transferred to mass production die casting programs, ensuring that the visual and functional standards defined in the initial phase are preserved.

Customers who need a fully consolidated route—from casting to finished assemblies—benefit from our one-stop manufacturing service, which integrates CNC finishing with coating, sub-assembly, and final packaging.

Application Examples for Premium CNC-Finished Surfaces

Premium CNC finishing is widely applied across industries:

GPU frames and electronic chassis similar to the Gigabyte GPU frame projects, where flatness and stiffness are critical for thermal modules

Consumer and communication housings like the Huawei aluminum housing collaborations require tight cosmetic and dimensional control

Power tool structures inspired by Bosch power tool housing projects, where tactile feel, robustness, and precision interfaces must all be balanced

In each case, CNC finishing routes are customized to meet a specific combination of mechanical, thermal, electrical, and aesthetic requirements.

Conclusion

Achieving premium surface quality in die cast components is the result of a complete engineering system, not a single polishing step. Starting from robust casting design and alloy selection, through well-sequenced deburring and conditioning, and finally through meticulously controlled CNC finishing, Neway delivers surfaces that support both high-end appearance and long-term functional reliability.

By combining die casting expertise, advanced finishing processes, and rigorous inspection, we help customers transform raw castings into premium components that align with the most demanding market expectations—whether in consumer electronics, automotive platforms, industrial systems, or emerging technology applications.

FAQs

What surface roughness levels can Neway typically achieve on CNC-finished die cast components?

How do you decide which areas of a die cast part require CNC finishing versus mass finishing only?

Can CNC finishing be combined with powder coating or anodizing without compromising dimensional accuracy?

How early should CNC finishing requirements be considered during die cast part design?

What inspection methods do you use to verify premium surface quality on production parts?