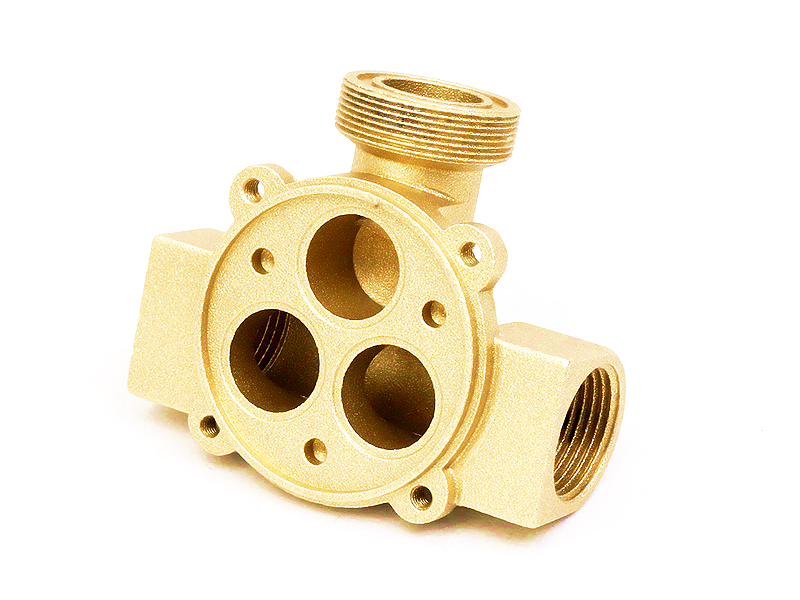

Custom Brass Die Casting Service for Corrosion-Resistant Plumbing Fittings

Plumbing systems demand reliable fittings that can withstand pressure, temperature fluctuations, and corrosive exposure to water, air, or chemicals over extended service lives. From faucets and valves to tees, elbows, and union joints, plumbing fittings must offer dimensional precision, mechanical integrity, and excellent corrosion resistance. Brass die casting offers a robust and scalable solution for producing these critical components, ensuring performance, longevity, and compatibility with industry-standard plumbing systems.

At Neway, we provide custom brass die casting services using high-performance copper-zinc alloys. With advanced tooling, pressure casting, and in-house finishing, we produce corrosion-resistant plumbing fittings that meet international codes and OEM specifications for commercial, residential, and industrial applications.

Why Brass Die Casting is Ideal for Plumbing Fittings

Brass alloys combine high strength, machinability, and corrosion resistance, making them ideal for water-handling components. Compared to machined or forged parts, high-pressure brass die casting enables cost-effective production of complex geometries with tighter dimensional tolerances and minimal material waste.

Key Benefits

Tensile strength: 350–550 MP,a depending on brass grade

Corrosion resistance: withstands chloride, sulfate, and mineral-rich water

Tight tolerances: ±0.02 mm achievable on sealing and thread features

Excellent machinability for threading, grooving, or valve seat preparation

High-pressure resistance for parts operating at 1.6–2.5 MPa (PN16–PN25)

Brass die casting supports integration of flanges, threads, grooves, and flow channels—all molded in a single cycle with minimal post-processing.

Applications in Plumbing and Fluid Systems

Brass fittings are used across a wide range of plumbing and HVAC systems due to their mechanical reliability and resistance to dezincification, scaling, and corrosion.

Component Type | Application Examples | Key Functional Requirements |

|---|---|---|

Valve Bodies | Angle valves, stop valves, ball valves | Pressure tolerance, corrosion resistance, accurate seat geometry |

Pipe Fittings | Elbows, tees, couplings, reducers | Leak-free sealing, dimensional stability, threaded precision |

Faucet and Tap Housings | Kitchen, bathroom, and lab faucets | Aesthetic surface, corrosion resistance, NSF/ANSI compliance |

Backflow Preventers | Check valves, non-return valves | Hydraulic performance, sealing integrity, consistent tolerance |

Meter Connectors | Utility system adapters, meter couplings | Impact resistance, precise threads, plating compatibility |

Brass Alloys Used for Plumbing Die Casting

Neway uses a range of copper/brass alloys that meet ASTM B584, EN 1982, and ISO 4261 standards for plumbing components.

Alloy | Copper (%) | Zinc (%) | Tensile Strength (MPa) | Best Applications |

|---|---|---|---|---|

Brass 360 | ~61 | ~35 | ~345 | High-machinability components, threaded parts |

Brass 380 | ~58 | ~38 | ~400 | General fittings, meter bodies, valve housings |

Brass 464 | ~62 | ~36 | ~480 | Marine-grade or high-corrosion fittings |

CuZn37 | ~63 | ~37 | ~450 | Thin-walled plumbing parts with decorative surfaces |

Alloys are selected based on strength, corrosion resistance, and machinability. Lead-free or low-lead options are available to meet California AB1953 and NSF/ANSI 61 standards.

Dimensional Accuracy and Sealing Integrity

Plumbing fittings require tight tolerances to ensure leak-free operation and compatibility with standard threading and sealing systems.

Wall thickness: 1.2–4.5 mm depending on part design

Thread tolerance: ±0.02 mm for NPT, BSP, or ISO metric threads

Flatness on sealing surfaces: ≤ 0.03 mm

Concentricity on multi-axis bores: ≤ 0.05 mm

Ra ≤ 1.6 µm on polished or machined surfaces

Neway uses in-line inspection and CMM metrology to ensure repeatability in high-volume production runs.

Surface Treatments for Water Contact and Corrosion Resistance

Brass plumbing fittings often require enhanced surface finishes for hygiene, aesthetics, and longevity. Neway offers post-processing solutions that meet industry durability standards.

Electroplating: chrome, nickel, or tin plating for faucet and valve components

Powder coating: corrosion-resistant finishes for colored fittings or underground applications

Polishing: mirror or satin finishes for exposed surfaces

Painting: marking or identification on specialized fittings

Assembly: integration of O-rings, seals, valve seats, or threads

All finishes conform to NSF/ANSI 61 for potable water use and are RoHS/REACH-compliant.

Tooling and Volume Capabilities

Neway supports fast and scalable production of brass plumbing components with full in-house tool and die making and casting operations.

Die steel: H13 tool steel, hardened and heat-resistant

Die life: 150,000 to 400,000 shots depending on alloy and part geometry

Tooling lead time: 3–5 weeks with DFM and mold flow analysis

Part cycle time: 25–40 seconds

Rapid prototyping available for testing thread compatibility, valve sealing, or component fit

We also offer low-volume runs for custom product lines and mass production for OEM-scale supply.

Case Study: Water Meter Coupling Set for Municipal Utility

A utility equipment supplier required a pair of brass die-cast connectors for a new water meter system. Specifications included:

Pressure rating: 2.5 MPa (PN25)

Thread standard: ISO 228-1 G thread, class A tolerance

Surface finish: nickel-plated exterior, Ra ≤ 1.4 µm

Volume: 300,000 sets per year

Requirements: thread gauge conformity, 100% pressure-tested

Neway selected Brass 380 for strength and castability, utilizing a 4-cavity tool design. Parts were electroplated, CNC machined, and assembled with O-ring seals. The solution exceeded hydrostatic burst and fatigue test criteria, with over 99.2% first-pass yield.

Why Plumbing OEMs Choose Neway

Neway is a trusted supplier to plumbing and fluid control system manufacturers worldwide:

Advanced brass casting with support for threaded, sealed, and machined components

ISO 9001:2015-certified production and material traceability

In-house surface finishing, threading, pressure testing, and assembly

Experience with global plumbing codes and lead-free compliance

Flexible support for OEM, ODM, or private-label product development

Neway ensures strength, safety, and precision at every production stage, whether you need faucet cores, manifold housings, or multi-port plumbing fittings.

Conclusion

Brass die casting is ideal for producing complex, corrosion-resistant plumbing fittings that meet strict dimensional, mechanical, and environmental standards. At Neway, our integrated approach to alloy selection, die design, casting, machining, and finishing ensures that every part meets your exact performance and regulatory requirements.

To learn more or request a quote for your plumbing fitting project, contact Neway today.

FAQs

What brass alloys are most corrosion-resistant for plumbing fittings?

Can die cast brass components be certified for drinking water use?

How precise are threads and seals in cast brass pipe fittings?

What post-processing options are available for aesthetic or functional coatings?

What is the lead time for tooling and sampling new brass fittings?