One-Stop Metal Casting Service: Streamlining Your Production Process

In today’s increasingly fast-paced manufacturing environment, efficiency, reliability, and flexibility are crucial to maintaining a competitive edge. Traditional supply chains that involve multiple vendors for design, tooling, casting, and post-processing are often prone to delays, quality inconsistencies, and cost overruns. At Neway, we solve this challenge with our fully integrated one-stop metal casting service, combining all essential manufacturing steps into a streamlined, centrally managed workflow.

In today’s increasingly fast-paced manufacturing environment, efficiency, reliability, and flexibility are crucial to maintaining a competitive edge. Traditional supply chains that involve multiple vendors for design, tooling, casting, and post-processing are often prone to delays, quality inconsistencies, and cost overruns. At Neway, we solve this challenge with our fully integrated one-stop metal casting service, combining all essential manufacturing steps into a streamlined, centrally managed workflow.

Our turnkey solution is ideal for OEMs, startups, and product developers seeking to accelerate time-to-market, reduce overhead, and maintain total quality control—from concept through to production and delivery.

What Is a One-Stop Metal Casting Service?

A one-stop metal casting service provides a comprehensive, vertically integrated solution for producing custom metal parts. Instead of working with different subcontractors for design, tooling, casting, machining, finishing, and assembly, clients rely on a single source, Neway, for all manufacturing requirements.

Our integrated offering includes:

By centralizing these capabilities under one roof, we enhance communication, reduce handoff errors, and ensure consistent standards across every phase of your product lifecycle.

Key Advantages of One-Stop Metal Casting

Faster Turnaround Times

Consolidating design, casting, machining, and finishing in a single facility significantly reduces lead times. Tooling development, which typically takes 4–6 weeks when outsourced, can be completed in as little as 2–4 weeks at Neway. Combined with real-time production scheduling and internal part handling, this integration enables rapid prototyping, concurrent engineering, and faster delivery of both pilot and production batches.

Built-In Quality Control

With our ISO 9001:2015-certified quality management system, we ensure rigorous inspection and process validation at each stage. Key quality assurance features include:

Mold flow analysis and DFM validation at the design stage

In-line dimensional inspection during die casting and machining

CMM verification, surface finish evaluation, and functional testing before delivery

Because we control the entire process, any deviation can be quickly addressed, minimizing scrap rates and warranty risk.

Lower Total Manufacturing Cost

A one-stop approach streamlines procurement, reduces logistical expenses, and eliminates duplication of overhead. Instead of managing multiple contracts, shipments, and production schedules, customers benefit from:

Consolidated vendor communication

Lower per-unit handling and packaging costs

Better pricing through volume bundling

Reduced risk of project delays and downtime

This model improves predictability and long-term cost efficiency, particularly for complex parts requiring secondary operations.

Full Engineering Support

Our in-house engineering team supports clients from the earliest design phase. We assist with:

Design for manufacturability (DFM) and cost optimization

Alloy selection based on strength, heat resistance, or conductivity

Draft angle, ribbing, and wall thickness recommendations for casting

Surface treatment and finishing strategies for corrosion resistance or aesthetics

This collaborative process ensures that every part is functional, castable, and ready for scale.

Comprehensive Casting Capabilities

Neway offers a wide range of casting processes tailored for different applications and production volumes.

Die Casting

Aluminum die casting: Lightweight, corrosion-resistant parts for automotive, aerospace, and electronics

Zinc die casting: High precision, fast-cycle parts with excellent surface finish and tight tolerances

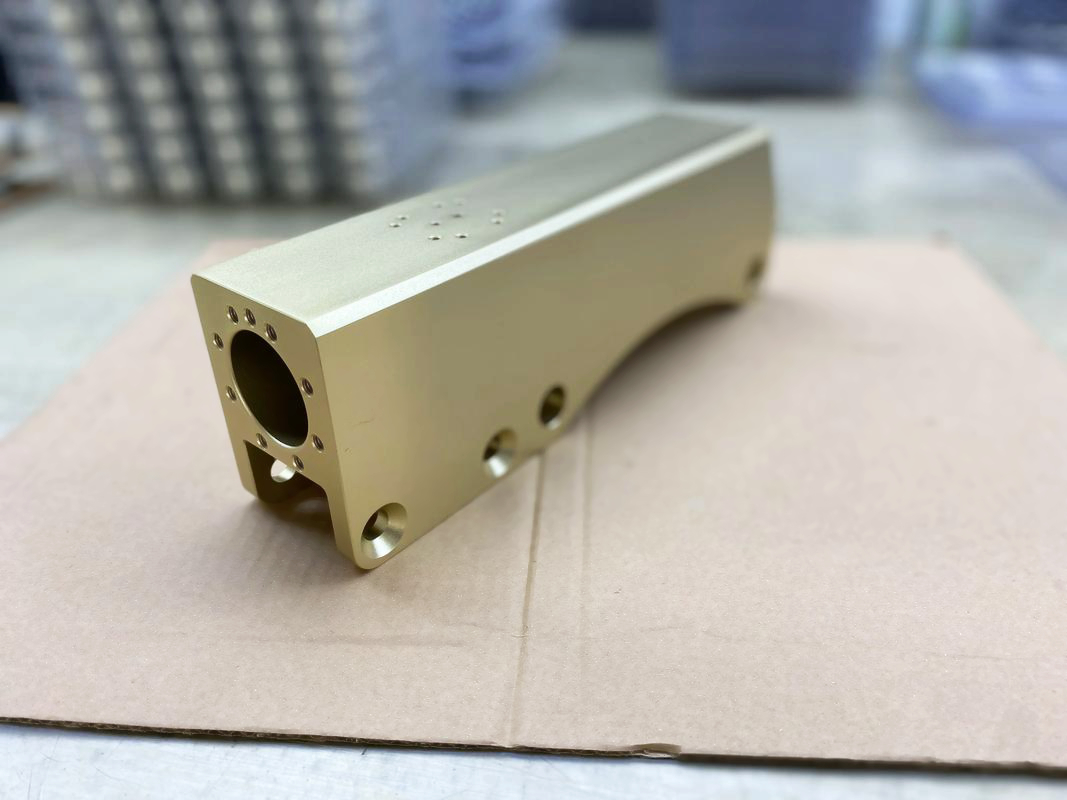

Copper/brass die casting: Durable components with excellent conductivity and resistance to marine environments

These processes are supported by high-pressure casting machines with automated shot control, temperature regulation, and robotic part handling.

Sand and Urethane Casting

For larger or low-volume parts:

Sand casting: Cost-effective for large, complex geometries

Urethane casting: Ideal for bridge production and plastic-like components requiring elastomeric behavior

Each process is selected based on production quantity, design complexity, and material requirements.

Integrated Post-Processing and Surface Treatments

To deliver finished parts, Neway performs all secondary and finishing operations in-house:

CNC machining: Features tolerances as tight as ±0.005 mm for holes, threads, and critical interfaces

Anodizing for aluminum oxidation protection

Powder coating and painting for cosmetic or corrosion resistance

Arc anodizing for enhanced wear resistance

Deburring and polishing: Sand blasting and tumbling to achieve the desired Ra values

Assembly: Manual and semi-automated integration of fasteners, seals, and inserts, followed by leak testing or function checks

With these services, customers receive complete, installation-ready components that meet all dimensional and aesthetic standards.

Industries and Applications

Neway’s one-stop metal casting service is tailored to support the unique requirements of various industries:

Automotive: Structural brackets, powertrain housings, EV battery cases

Aerospace: Lightweight frames, sensor enclosures, fuel system components

Electronics: Heat sinks, EMI shielding enclosures, terminal housings

Medical Devices: Diagnostic device casings, ergonomic tools, subassemblies

Industrial Equipment: Hydraulic valves, gearboxes, actuator mounts

Whether you need 100 prototypes or 1,000,000 production units, Neway’s vertically integrated process ensures scalable quality at every level.

Why Choose Neway?

Fully integrated design-to-delivery workflow

Decades of metal casting expertise across multiple materials

In-house capabilities for casting, machining, coating, and assembly

Certified quality systems and global customer support

Transparent communication and turnkey service

Neway simplifies your supply chain by becoming your trusted single-source casting partner, helping you innovate faster, lower costs, and launch products more efficiently.

Contact us today to request a quote or schedule a project consultation with our engineering team.