Precision-Manufactured Copper Alloy Die Cast Heat Exchangers for HVAC Systems

Modern HVAC systems use efficient, durable heat exchangers to maintain consistent climate control across residential, commercial, and industrial environments. Heat exchanger components must offer exceptional thermal conductivity, corrosion resistance, and structural integrity, whether used in condensers, evaporators, or fluid transfer modules. Copper alloy die casting provides a highly effective manufacturing method for producing intricate heat exchanger parts that meet today's HVAC systems' thermal and mechanical demands.

At Neway, we offer custom copper die casting services tailored for HVAC applications. Using premium copper and copper-based alloys, we deliver high-precision castings that maximize thermal transfer efficiency and maintain consistent quality across production volumes.

Why Use Copper Alloys for HVAC Heat Exchangers

Copper is widely recognized for its outstanding thermal conductivity (up to 400 W/m·K), high resistance to internal scaling, and natural corrosion resistance in water and refrigerant environments. Compared to extruded or brazed assemblies, die cast copper alloy components allow for complex, integrated shapes that improve efficiency while reducing assembly steps and leak potential.

Key Advantages

Thermal conductivity: 250–400 W/m·K depending on the copper alloy

Corrosion resistance in refrigerants, glycol, and saline solutions

Dimensional tolerance: ±0.02 mm for interface surfaces

Operating temperature range: -40°C to 200°C for HVAC environments

Fatigue resistance: reliable under cyclical thermal stress and vibration

Copper alloys also offer antimicrobial properties, making them ideal for HVAC applications in hospitals, food processing, and high-hygiene environments.

HVAC Applications for Copper Die Cast Components

Copper alloy die casting supports the production of precision heat transfer components with integrated fins, channels, and mounting structures.

Component Type | Application Examples | Functional Requirements |

|---|---|---|

Heat Exchanger Shells | Condenser housings, evaporator shells | Thermal efficiency, pressure containment, casting complexity |

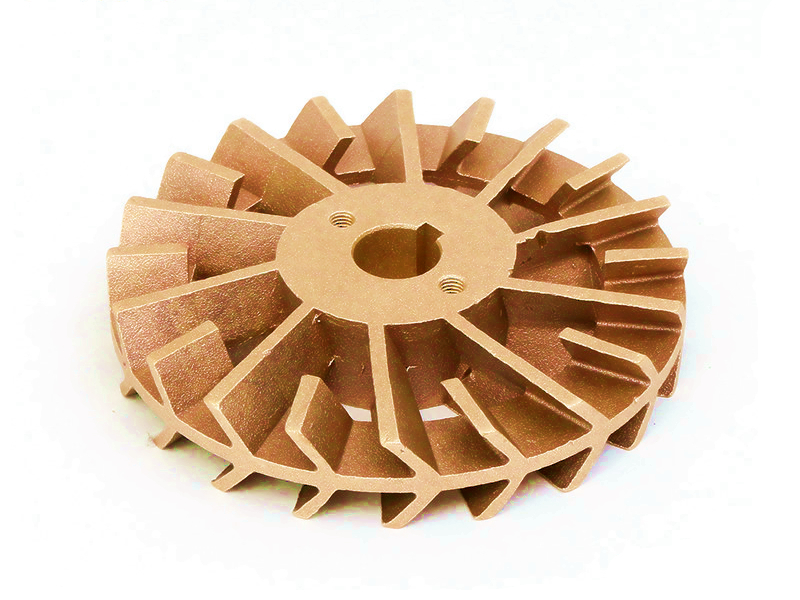

Cooling Fins & Plates | Integrated fin arrays for forced convection units | Thin wall geometry, corrosion resistance, consistent fin spacing |

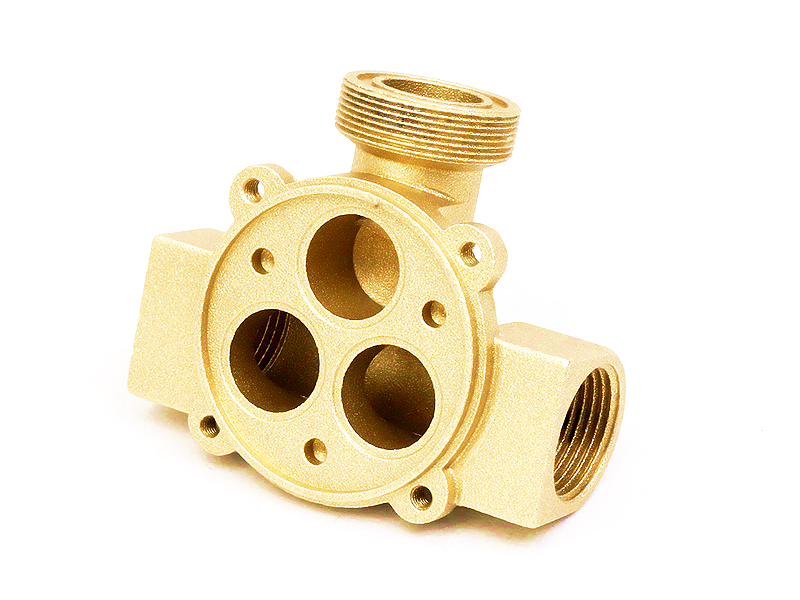

Liquid-to-Air Interfaces | HVAC fluid couplers, flow distributors | Sealing integrity, thermal conductivity, anti-vibration design |

Pump and Fan Housings | Circulator units, heat pump modules | Structural rigidity, dimensional accuracy, thermal control |

Multi-channel Blocks | Chillers, multi-circuit evaporators | Internal flow geometry, leak-proof construction, low porosity |

Copper Alloys Used in HVAC Die Casting

Neway uses a variety of copper alloys tailored to heat transfer and environmental exposure requirements. All materials meet ISO 1634-1, ASTM B148, and EN 1982 standards for cast copper alloys.

Alloy | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Best Use Cases |

|---|---|---|---|

C18200 | ~320 | ~340 | Pressure-bearing heat exchanger shells, fan housings |

CuZn37 | ~120 | ~450 | Flow channel blocks, general HVAC fluid handling parts |

C17500 | ~180 | ~600 (age-hardened) | Fatigue-resistant parts under cyclic stress |

CuNi10Fe1 | ~40 | ~400 | Marine HVAC and corrosion-prone environments |

C18200, a chromium-copper alloy, is commonly used for its conductivity, corrosion resistance, and castability in HVAC pressure components.

Design Considerations and Tolerances

HVAC heat exchanger components often require intricate internal pathways, thin walls, and tight tolerances for efficient heat exchange and modular integration.

Wall thickness: 1.0–2.5 mm for fins and channels

Tolerances: ±0.02 mm for mounting interfaces, sealing planes, or internal bores

Flatness on mating surfaces: ≤ 0.03 mm

Channel spacing accuracy: ≤ ±0.05 mm across multiple paths

Die casting enables parts with internal manifolds, bosses, undercuts, and thin ribs to be produced in a single cycle—minimizing solder joints and improving heat flow uniformity.

Surface Treatments and Anti-Corrosion Options

HVAC components are exposed to moisture, refrigerants, and sometimes mildly corrosive environments. Neway provides full in-house surface finishing for copper alloy components:

Electroplating: tin or nickel plating for corrosion and oxidation protection

Powder coating: protective coatings for fan housings and structural parts

Painting: color coding and anti-rust primers for outdoor systems

CNC post-machining: for sealing grooves, alignment pins, and heat contact surfaces

Assembly: including press-fit mounts, threaded inserts, or integrated seals

All finishes are RoHS and REACH compliant and can meet ASTM B117 and ISO 9227 salt spray resistance standards when required.

Tooling and Production for HVAC Parts

Neway offers full in-house tool and die making with tooling strategies optimized for fin density, internal flow paths, and thermal interfaces.

Tooling material: H13 tool steel hardened to withstand copper’s high melt temperatures

Tool life: 100,000–300,000 shots for copper alloy dies

Part cycle time: 30–50 seconds depending on wall thickness and cavity design

Rapid prototyping: includes fluid flow testing and early thermal validation

Casting size range: from 20 mm fittings to 300 mm multi-channel housings

Low-volume and mass production programs are supported, with batch inspection and thermal performance validation on request.

Case Study: Copper Heat Transfer Plate for Ducted HVAC Unit

An HVAC OEM required a copper-based heat exchanger core for a new high-efficiency ducted system. Requirements included:

Thermal conductivity > 250 W/m·K

Thin walls (1.4 mm) with internal micro-channel flow paths

Surface finish: Ra ≤ 1.5 µm after machining

Leak-proof at 3.5 MPa internal pressure

Production volume: 200,000 units annually

Neway selected C18200 for thermal and pressure performance. A 2-cavity mold with side cores produced the parts with integral inlet and outlet bosses. Machining and pressure testing followed casting. Tin plating was applied to prevent oxidation in humid environments. Final parts exceeded thermal transfer targets and passed all fatigue and burst testing.

Why HVAC Manufacturers Choose Neway

Neway delivers complete copper alloy casting solutions for HVAC OEMs and tier-1 suppliers:

ISO 9001:2015 certified manufacturing and full inspection traceability

Design-for-manufacturing support for thermal optimization

Casting + CNC + finishing + assembly under one roof

Fast tooling and reliable batch consistency

Global fulfillment for large-scale HVAC programs

Whether you are producing a small connector block or a complete heat exchanger shell, Neway ensures precise execution at scale.

Conclusion

Copper alloy die casting is a powerful solution for manufacturing heat exchanger and fluid components in HVAC systems. High thermal performance, corrosion resistance, and design flexibility enable the production of durable, energy-efficient components that meet the evolving needs of the HVAC industry. At Neway, we combine advanced copper alloy knowledge with robust tooling and quality control to deliver parts that keep systems running efficiently and reliably.

To discuss your HVAC project or request a quote, contact Neway today.

FAQs

What copper alloys offer the best thermal performance for HVAC applications?

Can copper die castings be used in refrigerant-based systems?

How are internal channels cast and validated in heat exchangers?

What finishing options prevent oxidation in high-humidity HVAC environments?

How quickly can prototype heat exchanger components be delivered?