¿Qué es la fundición a presión de aluminio? ¿Cómo calcular el costo?

Introduction: Why Is Aluminum Die Casting So Popular?

In today’s manufacturing landscape—where lightweight design, high strength, and high efficiency are in high demand—aluminum die casting has become a core manufacturing process across industries including automotive, telecommunications, electronics, and aerospace. It strikes an ideal balance between part performance, production cost, and efficiency. However, for many engineers and buyers new to this process, the cost structure often appears to be a “black box.” As a practical guide, this article—written from the perspective of senior engineers at Neway—walks you through the technical principles of aluminum die casting and a detailed breakdown of its cost composition, helping you make smarter sourcing and engineering decisions.

What Is Aluminum Die Casting?

Definition of Aluminum Die Casting

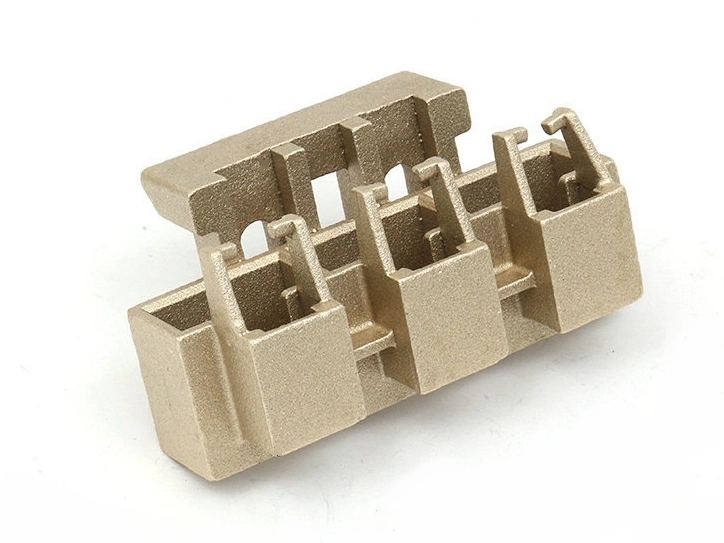

Aluminum die casting—formally known as aluminum alloy pressure die casting—is a precision casting process in which molten aluminum alloy is injected at high speed into a hardened steel mold cavity under high pressure, then rapidly cooled and solidified under pressure. In simple terms, it is similar to a “metal injection molding” process, enabling fast, repeatable mass production of metal parts with complex geometries, high dimensional accuracy, and smooth surfaces.

Step-by-Step Process of Aluminum Die Casting

A complete aluminum die casting cycle can be divided into the following key stages:

Mold preparation and spraying: The precision mold is installed on the die casting machine and preheated. Then, a release agent is evenly sprayed onto the cavity surface via a spraying system to facilitate part ejection after forming and extend mold life.

Mold clamping and pouring: The mold is locked under high clamping force to prevent metal leakage under pressure. Next, a dosing ladle transfers molten aluminum alloy from the holding furnace and pours it into the shot sleeve.

High-pressure injection and forming: This is the core of the process. The shot piston pushes molten metal into the mold cavity at very high speed and pressure. High pressure helps the metal fill fine corners and details, achieving sharp contours and precise features.

Intensification and cooling: After injection, pressure is maintained for a defined time to compensate for shrinkage during solidification, improving density and reducing shrinkage cavities.

Mold opening and ejection: Once the casting solidifies, the moving half retracts and separates from the fixed half. Ejector pins push the casting out of the mold, completing one cycle. The casting usually still carries runners, gates, vents, and other excess material, which must be removed and finished through subsequent die casting post-processing services.

Key Advantages of Aluminum Die Casting

High production efficiency: Die casting cycle times are short—often seconds to a few minutes—making it well-suited for high-volume production.

Excellent dimensional accuracy and surface quality: Castings offer tight tolerances and low surface roughness and can often be used directly or with minimal machining.

High strength with low weight: Aluminum alloys have low density, and the dense structure achieved under high-pressure forming provides an excellent strength-to-weight ratio.

Capability for complex thin-walled parts: High pressure improves fill capability, enabling complex geometries and thin walls that are difficult for other processes—especially when optimized through upfront die casting design services.

How to Calculate the Cost of Aluminum Die Cast Parts?

Overview of Cost Components

The total cost of an aluminum die cast part is far more than “material weight × unit price.” It is a composite cost consisting mainly of two categories: the one-time mold investment and the per-piece production cost allocated across the total production volume.

Mold Cost (One-Time Investment)

The mold is the “mother tool” of aluminum die casting and represents the primary initial investment of the project. Key factors influencing mold cost include:

Size and complexity: Larger parts and complex structures (multiple side cores, sliders, threads, or sealing features) require more complicated mold architectures and higher manufacturing cost.

Required mold life and mold materials: For very high expected production volumes, higher-grade mold materials with superior wear resistance and thermal fatigue strength are needed, such as H13 steel. These materials cost more upfront but deliver longer service life and better process stability.

Surface treatment and standard components: Cavity surface finish requirements, cooling layout complexity, and the brands/specs of standard components directly impact total mold cost.

Per-Piece Product Cost (Variable Cost)

This part of the cost scales with production volume and typically includes:

Raw material cost: Based on the net part weight and the consumption of aluminum alloy, while also accounting for runners, overflows, and scrap rates. Different alloy grades have different prices and performance—for example, the widely used A380 versus the more corrosion-resistant A360.

Production cost: Mainly machine hourly rates (depreciation + maintenance), melting/holding energy consumption, and operator labor.

Post-processing and secondary machining cost: A critical and often underestimated component. Depending on requirements, this may include:

Deburring and sandblasting cleanup.

High-precision CNC machining, i.e., post-machining of die castings to meet critical assembly dimensions.

Surface treatments to improve aesthetics or corrosion resistance, such as painting or anodizing.

Quality inspection and packaging cost: Includes in-process inspections, final dimensional checks, X-ray/CT when required, and any special packaging materials needed to prevent damage or corrosion.

A Simple Cost Calculation Model for Aluminum Die Casting

A simplified cost formula is:

Per-piece total cost = (Total mold cost ÷ Total production quantity) + Per-piece variable cost (materials + production + post-processing + inspection & packaging)

Example: For a part with a mold cost of 20,000 RMB and a planned production of 100,000 pieces, where the material cost per piece is 1 RMB, production cost is 0.5 RMB, post-processing is 0.8 RMB, and inspection & packaging is 0.2 RMB:

Per-piece total cost = (20,000 ÷ 100,000) + (1 + 0.5 + 0.8 + 0.2) = 0.2 + 2.5 = 2.7 RMB.

This shows that at high volumes, the amortized mold cost becomes a small fraction of unit cost, highlighting the effect of economies of scale.

Deeper Factors That Influence Aluminum Die Casting Costs

Part Design Complexity

Design is the origin of cost. A well-optimized design can significantly reduce cost without compromising functionality.

Draft angle: Appropriate draft enables smooth ejection, reduces galling, and extends mold life.

Uniform wall thickness: Avoiding localized heavy sections helps prevent shrinkage porosity, shortens solidification time, and improves yield.

Simplified internal structures: Reducing unnecessary complexity while meeting functional requirements lowers the difficulty and cost of die mold manufacturing.

Impact of Material Selection

Differences in performance and price among aluminum alloys directly affect cost. For example, ADC12 (often considered comparable to A383) offers excellent castability and stable mechanical properties, making it a cost-effective, widely used alloy. A360, with its strong corrosion resistance and good gas-tightness, is favored for harsher applications but comes with a higher material price. Selecting the right material—rather than simply choosing the highest-performance grade—is key to cost control.

Impact of Order Quantity on Unit Price

Order quantity is one of the most significant drivers of unit cost. For low-volume manufacturing projects, the allocated mold cost per piece is high, resulting in a higher total unit cost. In contrast, for mass production, mold cost is heavily diluted, and unit price approaches the variable cost baseline—maximizing overall cost efficiency.

Application Cases of Aluminum Die Casting in Various Industries

Automotive Industry

Aluminum die-cast parts play a crucial role in automotive lightweighting and are widely used in engine blocks, transmission housings, structural brackets, and other components. For example, in our Volkswagen supplier case, the ADC12 high-pressure precision die castings demonstrate a focus on dimensional accuracy, strength, and production stability.

Consumer Electronics and Telecommunications

From smartphone frames to telecom base station housings, aluminum die casting offers an ideal combination of strength, heat dissipation, and aesthetics. In our Huawei custom case, the database enclosure covers highlight capability in producing large, high-spec structural components.

Computer Hardware

Heatsinks, GPU frames, and related components are typical applications of aluminum die casting. In the Nvidia GPU frame case, the A380 die castings supplied support structural stability while enabling efficient thermal management.

Conclusion: Smart Investment Begins with Accurate Cost Estimation

Aluminum die casting is a technology-intensive, precision manufacturing process with a multidimensional cost structure. Understanding each stage—from molds and materials to post-processing—is essential for accurate estimation and effective cost control. By partnering with experienced suppliers like Neway—who provide comprehensive one-stop die casting services—you gain not only transparent quotations but also engineering optimization support from the product design phase onward, helping reduce cost at the source and improve project success rates.