Расчёт стоимости литья под давлением из меди и латуни

Введение: почему прецизионные отливки под давлением из меди и латуни такие дорогие?

Среди всех материалов для литья под давлением медь и латунь выделяются как предпочтительные варианты для требовательных применений благодаря исключительной электропроводности, теплопроводности, коррозионной стойкости и механическим свойствам. Как старший инженер Newway, я часто слышу от клиентов один и тот же ключевой вопрос: «Почему отливки под давлением из медных сплавов значительно дороже деталей из алюминиевых и цинковых сплавов?» Ответ кроется в уникальных характеристиках медных сплавов и сложности процессов их литья. Понимание факторов, формирующих стоимость таких деталей, — первый важнейший шаг к оптимальным решениям по закупкам.

Обзор процесса литья под давлением меди/латуни и его влияние на стоимость

Особые сложности литья под давлением медных сплавов

В отличие от металлов с более низкой температурой плавления, таких как алюминий и цинк, медные сплавы плавятся и льютcя при температурах выше 900°C, что создаёт две основные сложности. Во-первых, чрезвычайно высокая температура плавления требует более современного плавильного оборудования и значительно большего энергопотребления. Во-вторых, сильнейший термоудар от высокотемпературного расплава резко снижает ресурс пресс-формы, что вынуждает применять более высококлассные инструментальные стали и более жёсткие режимы термообработки — и это напрямую увеличивает стоимость изготовления пресс-форм. Кроме того, расплавы медных сплавов очень склонны к окислению, что требует более точного контроля процесса и защитных мер. Все эти факторы повышают сложность технологии и общую себестоимость производства.

Ключевые этапы производства и их связь со стоимостью

Полный цикл литья под давлением медных сплавов включает несколько точных стадий, каждая из которых тесно связана с итоговой стоимостью изделия. Процесс начинается с проектирования и изготовления формы из высококлассных инструментальных сталей (например, инструментальная сталь H13), что формирует сравнительно высокие первоначальные инвестиции. На этапах плавки и впрыска специализированные выдерживающие печи и высокотемпературные системы впрыска потребляют значительное количество энергии. На этапе высокоскоростного формования под высоким давлением, чтобы справляться с экстремальными температурами, часто требуются более частое обслуживание формы и более короткие непрерывные производственные серии, что напрямую влияет на эффективность и стоимость. Глубокое понимание этих деталей помогает ясно увидеть структуру затрат в наших коммерческих предложениях по услуге литья под давлением медных сплавов.

Детальная структура стоимости прецизионных медных деталей

Стоимость сырья: основной переменный фактор

Колебания рыночных цен на медь, цинк, олово и другие металлы — главный драйвер стоимости сырья. По сравнению с относительно стабильными ценами на алюминий, цены на медные сплавы сильнее зависят от мировых товарных рынков. При расчёте стоимости мы учитываем не только чистую массу готовой детали, но и дополнительный расход на литниковые системы, впускные каналы, вентиляционные элементы и другие технологические особенности. Эти вспомогательные структуры обычно составляют 20%–40% общего расхода материала и являются критически важной составляющей, которую нельзя игнорировать при точной оценке себестоимости.

Стоимость формы и оснастки

Формы для литья медных сплавов под давлением должны выдерживать экстремальные циклические термонагрузки, поэтому требуются более высококлассные стали и более сложные процедуры термообработки. В результате их первоначальная стоимость обычно на 30%–50% выше, чем у сопоставимых форм для литья алюминия под давлением. Однако при правильно запланированных объёмах производства эти разовые инвестиции можно распределить на большое количество изделий. Для заказов на десятки тысяч и более стоимость формы становится почти незаметной в цене за штуку — это и есть эффект масштаба.

Производственные затраты и эффективность

Из-за высокотемпературной природы медных сплавов их циклы литья под давлением обычно примерно на 20% длиннее, чем у алюминия. Это означает меньший выпуск при той же единице машинного времени, что повышает почасовые затраты на оборудование и энергопотребление. Одновременно, чтобы обеспечить стабильное качество продукции, требуется более частый мониторинг параметров процесса и более строгий контроль качества — эти мероприятия по обеспечению качества также составляют значительную долю общей себестоимости.

Постобработка и затраты на прецизионную мехобработку

Отливки «как отлиты» должны пройти серию операций постобработки, прежде чем станут полностью соответствующими требованиям прецизионными компонентами. Базовые операции включают удаление заусенцев и пескоструйную обработку для удаления облоя по линии разъёма и улучшения качества поверхности. Для обеспечения жёстких сборочных допусков часто требуется прецизионная CNC-обработка, то есть постмехобработка литых под давлением деталей. В зависимости от условий эксплуатации могут понадобиться дополнительные поверхностные обработки, такие как гальваническое покрытие или специализированное анодирование (или аналогичные защитные покрытия) — каждый этап увеличивает общую стоимость.

Как ключевой выбор материала влияет на стоимость и характеристики

Распространённые медные сплавы для литья под давлением и их ценовое позиционирование

Разные медные сплавы дают разные балансы стоимости и характеристик. Латунь Brass 360 широко используется благодаря отличной обрабатываемости и достойным механическим свойствам, что делает её экономичным универсальным вариантом — особенно для деталей, требующих значительной последующей мехобработки. Кремнистая бронза C65500 обеспечивает более высокую прочность и выдающуюся коррозионную стойкость, поэтому идеально подходит для морской и химической среды, хотя и при более высокой стоимости материала. Алюминиевая бронза C95400 — премиальный вариант с очень высокой прочностью, твёрдостью и износостойкостью; её часто применяют для критически важных узлов тяжёлой техники — разумеется, это и самый дорогой вариант.

Свойства материала и совокупная стоимость владения

Рациональные решения принимаются не по «цене за штуку», а по «совокупной стоимости владения». Более дорогой, износостойкий материал может существенно снизить частоту замен и затраты на обслуживание со временем. В жёстких условиях эксплуатации выбор высокопроизводительного материала, несмотря на более высокую стартовую стоимость, помогает избежать преждевременных отказов и дорогих простоев, в итоге оказываясь более экономичным на протяжении всего жизненного цикла изделия.

Типичные высокоценные отрасли применения отливок под давлением из меди/латуни

Электротехническая и электронная промышленность

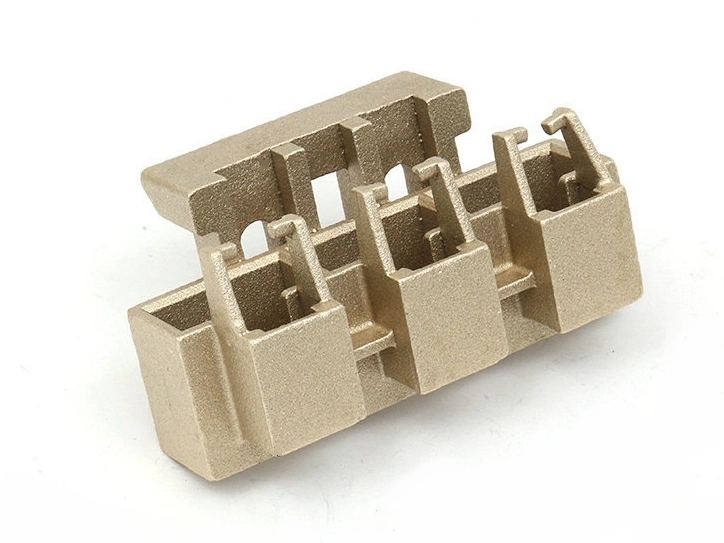

В электротехнической отрасли непревзойдённая проводимость медных сплавов делает их предпочтительным материалом для критически важных компонентов, таких как элементы выключателей, токопроводящие клеммы и разъёмы. В этих применениях электрические характеристики и надёжность значительно важнее самой стоимости материала — именно здесь наши возможности литья под давлением медных сплавов создают ключевую ценность.

Сантехника и арматура

Сантехническая отрасль давно опирается на латунь благодаря её отличной коррозионной стойкости и механическим свойствам. Корпуса клапанов, фитинги и шестерни из латуни Brass 360 выдерживают длительное давление воды и коррозионные среды, обеспечивая безопасную и надёжную работу систем водоснабжения.

Тяжёлое машиностроение и аэрокосмическая отрасль

Для чрезвычайно требовательных применений — например, высоконагруженных шестерён и втулок подшипников в тяжёлой технике или критических компонентов в аэрокосмической сфере — алюминиевая бронза C95400 обеспечивает исключительную прочность и износостойкость, становясь материалом выбора. В таких сценариях надёжность детали напрямую влияет на безопасность системы, и стоимость материала отходит на второй план.

Как оптимизировать конструкцию, чтобы контролировать стоимость литья меди под давлением?

Проектирование с учётом технологичности (DFM)

Грамотный дизайн изделия может значительно снизить стоимость медных отливок под давлением. Правильные углы уклона обеспечивают лёгкое извлечение, равномерная толщина стенок минимизирует перегревы и усадочные дефекты, а упрощение внутренних структур уменьшает сложность формы и трудоёмкость производства. Практика показывает, что конструкция, оптимизированная специально под литьё под давлением, может снизить общую стоимость более чем на 20% по сравнению с не оптимизированным дизайном.

Раннее взаимодействие с экспертами

Привлечение производственных экспертов на ранней стадии проекта — один из самых эффективных способов контроля затрат. Наша команда услуг проектирования для литья под давлением может дать профессиональные рекомендации уже на этапе разработки, внося целевые конструктивные корректировки, чтобы заранее избежать потенциальных проблем производства и обеспечить экономию с самого начала.

Использование прототипирования для валидации

Для принципиально новых конструкций использование быстрого прототипирования и мелкосерийного производства для проверки — эффективная стратегия, позволяющая избежать дорогостоящих ошибок в серийном производстве. Хотя этот шаг может увеличить начальные сроки и затраты, он значительно дешевле, чем переделка форм, доработка, или брак из-за конструктивных проблем, выявленных уже после запуска массового производства, тем самым существенно снижая общий риск проекта.

Заключение: инвестируйте разумно в ценность, а не только в цену

Стоимость медных и латунных отливок под давлением — результат совокупного влияния свойств материала, сложности процесса, конструкции изделия и требований к постобработке. При выборе поставщика важно смотреть дальше цифр в коммерческом предложении и тщательно оценивать опыт, технические возможности и систему управления качеством в литье медных сплавов под давлением. Сотрудничая с компанией вроде Newway, обладающей глубокой экспертизой в литье под давлением медных сплавов и предоставляющей комплексные услуги «под ключ», вы получаете больше, чем просто поставщика деталей — вы получаете технического партнёра, который поможет оптимизировать конструкцию и сбалансировать стоимость и характеристики.

Часто задаваемые вопросы (FAQ)

На сколько процентов медные отливки под давлением обычно дороже алюминиевых?

Какие факторы сильнее всего влияют на конечную цену медных литых под давлением деталей?

Как получить конкурентную цену для малых партий индивидуальных медных деталей?

Какие успешные кейсы есть у Newway в литье под давлением медных сплавов?