Sustratos aplicables para el anodizado por arco: metales para mejora superficial

Sustratos aplicables para el anodizado por arco: metales adecuados para la mejora superficial

Descripción general del anodizado por arco

Como ingeniero en Neway, trabajo estrechamente con clientes que requieren recubrimientos avanzados tipo cerámica para fines estructurales, térmicos o de aislamiento eléctrico. El anodizado por arco—también conocido como oxidación por microarco (MAO) u oxidación electrolítica por plasma (PEO)—sigue siendo una de las tecnologías de mejora superficial más eficaces para metales ligeros. Dado que este proceso se basa en la descarga de plasma en la interfaz metal–electrolito, no todos los metales son sustratos adecuados para este proceso. La selección de la aleación correcta determina el rendimiento del recubrimiento, la eficiencia de costos y la durabilidad a largo plazo.

Para respaldar la toma de decisiones de ingeniería, este artículo examina qué metales son más adecuados para el anodizado por arco, por qué ciertas aleaciones responden de manera más favorable al proceso y cómo la elección del sustrato afecta la calidad del recubrimiento en entornos reales de fabricación. Los procesos previos, como la fundición a presión de aluminio, la fundición a presión de zinc o la fundición a presión de cobre, también influyen en el comportamiento del MAO, lo que hace que la selección del material sea aún más crítica.

Factores clave que afectan la compatibilidad del sustrato

Conductividad eléctrica y estabilidad de descarga

Los materiales con conductividad moderada forman canales de plasma estables, lo que da como resultado capas de óxido cerámico uniformes. Las aleaciones de aluminio, por ejemplo, producen patrones de descarga predecibles, mientras que los metales altamente conductores como el cobre puro desestabilizan la ignición del arco.

Comportamiento de crecimiento de la capa de óxido

El MAO crea un recubrimiento cerámico grueso y duro. Las características de óxido inherentes de la aleación—tasa de densificación, distribución de poros y expansión térmica—determinan esencialmente la calidad final del recubrimiento. Un crecimiento de óxido consistente es esencial para componentes producidos mediante mecanizado CNC o fundición a presión.

Conductividad térmica y estabilidad al choque térmico

Las descargas de plasma generan altas temperaturas localizadas. Los metales con mayor conductividad térmica disipan el calor con más eficacia, reduciendo el riesgo de microgrietas. Las aleaciones con alto contenido de silicio, como el aluminio A380 o la aleación ADC12, requieren parámetros de control más estrictos debido a su menor conductividad térmica.

Composición química y elementos de aleación

Elementos como el silicio, el cobre y el zinc influyen en el comportamiento de oxidación. Su presencia afecta el umbral de descarga, la morfología cerámica y la dureza del recubrimiento.

Metales adecuados para el anodizado por arco

Aluminio y aleaciones de aluminio

El aluminio sigue siendo el material base más compatible para el anodizado por arco. Tanto las calidades fundidas como las forjadas presentan buena formación de óxido y un comportamiento de microarco estable. Por eso el aluminio se usa ampliamente en los sectores de electrónica de consumo, automoción y aeroespacial.

Aleaciones de fundición

Las aleaciones fundidas como AlSi10Mg y las calidades de alto silicio responden de forma diferente. Las aleaciones con alto silicio producen recubrimientos más duros pero más porosos, mientras que las calidades forjadas con menor silicio generan estructuras más lisas. Una lista completa de composiciones compatibles se puede encontrar en nuestra base de datos de aleaciones de aluminio.

Aleaciones forjadas

El aluminio forjado generalmente ofrece una uniformidad superior del recubrimiento debido a un menor contenido de impurezas y una mejor estabilidad térmica.

Magnesio y aleaciones de magnesio

El magnesio es altamente adecuado para el MAO. Sus características de ligereza y su comportamiento de oxidación favorable lo hacen ideal para aplicaciones donde la relación resistencia-peso es importante. Los recubrimientos MAO en magnesio mejoran significativamente la resistencia al desgaste y el desempeño frente a la corrosión.

Titanio y aleaciones de titanio

Las aleaciones de titanio pueden someterse a MAO para mejorar la biocompatibilidad y la dureza superficial. Aunque es más especializado que el aluminio y el magnesio, el MAO en titanio es común en soportes aeroespaciales, implantes médicos y componentes de aislamiento.

Aleaciones de zinc y cobre (viabilidad selectiva)

Las aleaciones de zinc y cobre se usan con menos frecuencia, pero pueden tratarse bajo condiciones controladas. Las aleaciones de zinc requieren modos de plasma de menor energía para evitar el derretimiento superficial. Las aleaciones a base de cobre enfrentan desafíos debido a su alta conductividad, pero composiciones específicas aún pueden modificarse mediante electrolitos ajustados.

Ventajas y comportamiento de las aleaciones de aluminio en MAO

Aleaciones fundidas de alto silicio

Aleaciones como el aluminio A380 y ADC12 exhiben una actividad de plasma vigorosa debido a su contenido de silicio. Estas aleaciones requieren una modulación precisa del voltaje, pero crean capas cerámicas excepcionalmente duras, ideales para carcasas mecánicas.

Aluminio de bajo silicio o forjado

Estas aleaciones generan recubrimientos más lisos y uniformes. Se prefieren para MAO decorativo o productos que requieren un control estricto de tolerancias.

Recomendado para carcasas estructurales y térmicas

Muchas carcasas aeroespaciales y de electrónica dependen de estructuras de aluminio fundido producidas mediante fundición a presión de zinc o fundición a presión de cobre y acabadas con MAO.

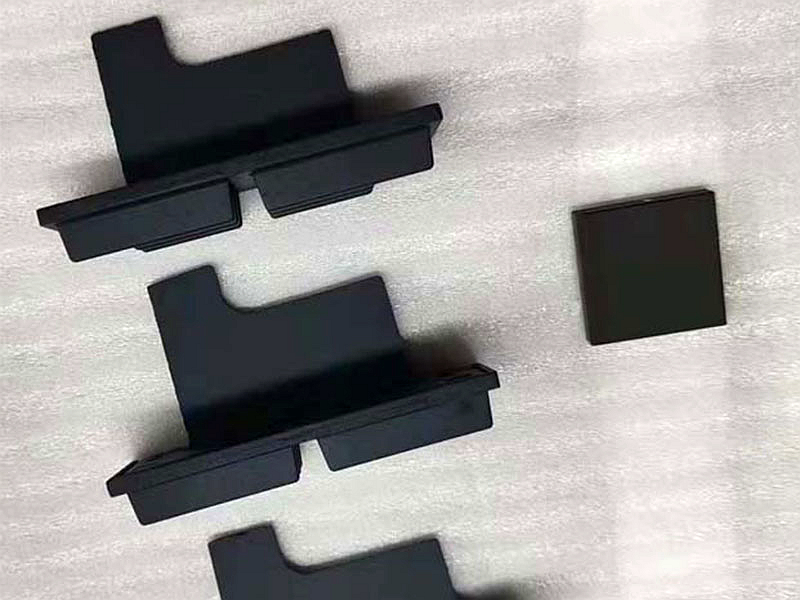

El MAO se usa comúnmente para carcasas presentes en carcasas de electrónica de consumo debido a su excelente resistencia al desgaste y atractivo estético.

Flujo integrado de fundición a presión → mecanizado → MAO

Nuestro flujo de trabajo integrado, que incluye prototipado rápido y producción en masa, garantiza que los sustratos de aluminio fundido estén optimizados para descargas de plasma, mejorando así la consistencia del recubrimiento y el rendimiento (yield).

Rendimiento de aleaciones de magnesio en MAO

Ventajas estructurales de ligereza

El magnesio destaca en industrias que requieren una reducción de peso agresiva. El MAO crea una capa cerámica que es a la vez ligera y extremadamente duradera.

Relevancia en la industria

En los sectores automotriz y aeroespacial, las carcasas y cubiertas de magnesio se benefician del MAO debido a su resistencia al calor y un mejor desempeño frente a la fatiga.

Riesgos térmicos

Las aleaciones de magnesio pueden sobrecalentarse bajo descargas de plasma intensas. Un control térmico adecuado y el diseño del electrolito son esenciales para prevenir el derretimiento local.

Aplicaciones de aleaciones de titanio

Biocompatibilidad y dureza

El MAO en titanio produce capas cerámicas porosas que son ideales para implantes, unión superficial y refuerzo estructural.

Uso aeroespacial

El MAO en titanio se utiliza en soportes aislantes, conectores y herrajes de fijación donde se requiere resistencia y aislamiento.

Beneficios de aislamiento eléctrico

El titanio presenta una excelente mejora de la rigidez dieléctrica bajo MAO, lo que lo hace adecuado para módulos electrónicos especializados.

Metales no adecuados para el anodizado por arco

Aleaciones con alto contenido de cobre

Debido a su alta conductividad eléctrica, las aleaciones de cobre desestabilizan la descarga del arco.

Aleaciones con alto contenido de zinc

Aunque algunas aleaciones de zinc pueden operar bajo condiciones controladas, las composiciones con alto zinc a menudo generan calor excesivo y defectos superficiales.

Metales de bajo punto de fusión

El estaño, el plomo y metales similares se funden antes de que puedan formarse arcos estables.

Aceros y aleaciones de hierro

El acero es incompatible con el MAO; en su lugar deben utilizarse recubrimientos cerámicos alternativos o recubrimientos PVD.

Cómo la elección del sustrato determina el rendimiento del recubrimiento

Resistencia a la corrosión

Los materiales con capas de óxido estables proporcionan una protección superior frente a la corrosión a largo plazo.

Resistencia al desgaste y dureza

Los sustratos de aluminio y magnesio pueden lograr superficies cerámicas extremadamente duras mediante MAO.

Capacidad de aislamiento eléctrico

El MAO incrementa significativamente la rigidez dieléctrica de los sustratos compatibles, especialmente para carcasas electrónicas.

Estabilidad del proceso y costo

Los sustratos que producen patrones de descarga predecibles reducen el desperdicio y los costos de recubrimiento. Cuando se combina con el anodizado para piezas fundidas a presión, el MAO puede mejorar el rendimiento manteniendo la eficiencia de costos mediante estrategias híbridas de recubrimiento.

Aplicaciones de materiales específicas por industria

Aeroespacial

El MAO se utiliza ampliamente en carcasas estructurales, soportes, escudos térmicos y otros componentes aeroespaciales que requieren alto desempeño frente al desgaste y el calor.

Automotriz

En carcasas de baterías para vehículos eléctricos y componentes del tren motriz, el MAO mejora la durabilidad. Los componentes fundidos a alta presión a menudo se desarrollan mediante soluciones de fundición automotriz y se tratan con MAO.

Electrónica de consumo

Las carcasas delgadas como carcasas de electrónica de consumo se benefician de recubrimientos cerámicos decorativos y funcionales.

Aplicaciones industriales

Las carcasas industriales usan MAO para mejorar el aislamiento, la resistencia a la corrosión y la vida útil.

Seleccionar el material adecuado para MAO

Necesidades de la aplicación

Los entornos de alta temperatura favorecen el aluminio con silicio, mientras que las piezas estructurales pueden requerir aleaciones forjadas.

Integración con fundición y mecanizado

Seleccionar materiales compatibles con los procesos previos mejora los resultados del recubrimiento. Integrar la producción en una sola plataforma—como el servicio integral de fundición a presión de Neway—simplifica el control de calidad.

Alternativas optimizadas en costo

Algunas aplicaciones pueden pasar de titanio a aluminio sin comprometer el rendimiento. Otras pueden optar por aluminio fundido en lugar de aluminio forjado para una mayor eficiencia de costos.

Colaboración con el proveedor

Trabajar estrechamente con su socio de fabricación garantiza un mejor DFM/DFAA y selección del sustrato, lo que a su vez mejora el rendimiento (yield) y el desempeño del MAO.

Resumen

El anodizado por arco ofrece recubrimientos cerámicos excepcionales, pero su éxito depende en gran medida de la selección del sustrato. Las aleaciones de aluminio y magnesio siguen siendo las opciones más fiables. El titanio aporta un rendimiento sólido en nichos específicos, mientras que las aleaciones de zinc y cobre requieren un ajuste cuidadoso de parámetros. Comprender el comportamiento metalúrgico de cada aleación permite a los ingenieros combinar MAO con procesos de fabricación óptimos—desde la fundición hasta el mecanizado y el tratamiento superficial—asegurando un desempeño consistente y eficiencia de costos.