Что такое литьё под давлением из цинка Zamak? Пошаговое руководство

Введение: почему литьё под давлением цинковых сплавов так популярно?

В производстве прецизионных металлических компонентов литьё под давлением цинковых сплавов занимает уникальное и практически незаменимое место благодаря своим очевидным преимуществам. Как инженер Newway по литью под давлением, я видел, как многие заказчики успешно повышали и качество продукции, и экономическую эффективность, выбирая литьё цинка. Будь то визуально безупречные потребительские изделия или размерно-точные промышленные детали — цинковое литьё под давлением стабильно даёт превосходный результат. В этой статье мы разберём технические детали процесса и последовательно рассмотрим полный производственный маршрут — от сырья до готовой детали.

Что такое литьё под давлением цинкового сплава (Zamak)?

Определение литья под давлением цинкового сплава

Литьё под давлением цинкового сплава — это производственный процесс, при котором расплавленный цинковый сплав впрыскивается в полость прецизионной пресс-формы под высоким давлением и быстро охлаждается, формируя требуемую геометрию детали. Процесс особенно подходит для деталей малого и среднего размера со сложной конструкцией и жёсткими требованиями по размерам. Ключевой материал — Zamak: сплав цинка, алюминия, магния и меди; название “Zamak” образовано от начальных букв этих элементов на немецком языке.

Ключевые свойства сплавов Zamak

Сплавы Zamak сочетают выдающиеся свойства, которые делают их идеальными для литья под давлением. Во-первых, они обладают отличной жидкотекучестью, что обеспечивает полное заполнение тонких элементов формы и даёт гладкую поверхность и чёткие контуры. Во-вторых, цинковые сплавы демонстрируют высокую механическую прочность: предел прочности при растяжении может достигать примерно 358 МПа, а твёрдость по Бринеллю — около 82 HB, что превосходит многие инженерные пластики и некоторые алюминиевые сплавы. Кроме того, цинковые сплавы отлично подходят для отделки поверхности и хорошо совместимы с различными процессами гальваники и нанесения покрытий.

Литьё цинкового сплава под давлением в сравнении с другими видами литья

По сравнению с литьём алюминия под давлением цинковые сплавы имеют более низкую температуру плавления (примерно 380–420°C), что снижает энергопотребление и уменьшает термический удар по форме, продлевая ресурс пресс-формы. По сравнению с магниевым литьём под давлением цинковое литьё выигрывает по управляемости затрат и зрелости технологии. В тонкостенных деталях цинковые сплавы особенно сильны: они надёжно обеспечивают толщины стенки до 0,5 мм — важное преимущество во многих конструкторских задачах.

Пошаговый процесс литья под давлением цинкового сплава

Шаг 1: проектирование и изготовление пресс-формы

Прецизионная пресс-форма — основа литья цинковых сплавов под давлением: её качество напрямую определяет точность и стабильность конечной продукции. Наша команда изготовления пресс-форм использует современное ПО и оборудование, чтобы каждая форма соответствовала строгим техническим требованиям. При проектировании необходимо комплексно учитывать усадку сплава, углы уклона, компоновку каналов охлаждения и вентиляцию, а также обеспечивать достаточную прочность и износостойкость для поддержки серийного производства.

Шаг 2: плавка и подготовка сплава

Плавка сплава Zamak должна выполняться при строго контролируемой температуре, обычно около 420°C. Мы используем автоматизированные системы плавки, чтобы обеспечивать однородность состава и стабильное качество сплава. Во время плавки особое внимание уделяется предотвращению загрязнения железом: даже следовые количества железа могут ухудшать жидкотекучесть и механические свойства.

Шаг 3: смыкание формы и впрыск

После подготовки формы и достижения сплавом оптимального состояния расплава машина литья под давлением прикладывает усилие запирания порядка 50–100 МПа для фиксации формы. Затем поршень (плунжер) впрыскивает расплавленный цинковый сплав в полость со скоростью примерно 15–45 м/с. На этом этапе критична точность по времени: весь впрыск обычно занимает 0,01–0,2 секунды, чтобы сплав успел заполнить все участки до начала кристаллизации.

Шаг 4: охлаждение и затвердевание

После впрыска отливка охлаждается и затвердевает внутри формы. Благодаря высокой скорости кристаллизации цинковых сплавов этот этап относительно короткий — обычно всего несколько секунд. Водяные каналы охлаждения в форме точно контролируют температуру, обеспечивая равномерное охлаждение и снижая риск дефектов — усадки, пористости или деформаций из-за чрезмерных температурных градиентов.

Шаг 5: раскрытие формы и выталкивание

Когда отливка достаточно затвердеет, машина автоматически раскрывает форму. Затем включается инженерно рассчитанная система выталкивания: выталкиватели (штифты) аккуратно извлекают отливку из полости. Для этого требуется точная синхронизация и контролируемое усилие, чтобы обеспечить лёгкое извлечение без деформации детали и повреждения поверхности.

Шаг 6: обрезка и удаление литников

После извлечения на отливке остаются литники, питатели, переливы и прочие технологические элементы, которые удаляются с помощью специальных обрезных штампов. Операция обычно интегрируется в автоматическую линию, чтобы гарантировать стабильные размеры. Обрезки и литниковая система сразу же возвращаются в переработку, что подчёркивает экологичность и 100% перерабатываемость цинковых сплавов.

Финишная обработка и поверхностные покрытия после литья

Базовые операции очистки и доводки

После первичной обрезки требуется дополнительное улучшение поверхности. Мы применяем механические методы удаления заусенцев, используя прецизионное виброабразивное оборудование для снятия мелких заусенцев по кромкам. Для деталей со специальными требованиями к внешнему виду может применяться пескоструйная обработка, обеспечивающая равномерную матовую фактуру или заданные текстуры. Эти операции не только улучшают внешний вид, но и создают качественную основу для последующих покрытий.

Точная вторичная мехобработка

Для зон, требующих повышенной точности, мы предлагаем профессиональные услуги постобработки (мехобработки) отливок. Используя высокоточное оборудование ЧПУ-обработки, мы можем «довести» критические размеры до строгих сборочных допусков. Такой комбинированный подход объединяет высокую производительность литья под давлением и точность мехобработки, обеспечивая оптимальную себестоимость.

Покрытия для улучшения внешнего вида и эксплуатационных свойств

Цинковые сплавы хорошо совместимы с широким спектром процессов отделки. В зависимости от требований мы можем предложить гальваническое покрытие, окраску жидкими материалами или порошковую окраску. Гальваника придаёт деталям премиальный металлический вид и существенно повышает коррозионную стойкость. Порошковое покрытие обеспечивает богатую палитру цветов и долговечный защитный слой, что делает его подходящим как для функциональных, так и для декоративных изделий.

Выбор материала: понимание семейства Zamak

Zamak 3: универсальный выбор

Zamak 3 — наиболее распространённый цинковый сплав для литья под давлением, известный отличной жидкотекучестью и размерной стабильностью. Он особенно хорошо подходит для сложных тонкостенных деталей и уверенно работает в широком спектре промышленных и потребительских применений. Сбалансированные свойства и выгодная стоимость делают его первым выбором во многих проектах.

Zamak 5: повышенная прочность и твёрдость

Когда детали должны выдерживать более высокие нагрузки или износ, Zamak 5 становится отличным вариантом. Благодаря примерно 1% меди он обеспечивает примерно на 10% более высокую прочность и твёрдость по сравнению с Zamak 3 при сохранении хорошей литейной технологичности. Сплав широко применяется для элементов замков, фурнитуры и инструментальных компонентов, где требуется улучшенная механика.

Другие специальные цинковые сплавы

Помимо стандартной серии Zamak, мы предлагаем ряд специальных цинковых сплавов, разработанных под уникальные требования различных применений. Например, ZA-8 и аналогичные сплавы обеспечивают более высокую рабочую температурную стойкость при сохранении хороших литейных свойств, а некоторые низкомедные составы оптимизируются для улучшения гальванопокрытия в декоративных или функциональных целях.

Ключевые преимущества литья под давлением цинковых сплавов

Литьё под давлением цинковых сплавов выделяется среди многих производственных методов сочетанием сильных сторон. Оно обеспечивает очень высокую размерную точность: типичные допуски могут удерживаться в пределах ±0,05 мм, что удовлетворяет большинство требований прецизионной сборки. Процесс поддерживает тонкостенные конструкции с минимальной толщиной стенки до 0,5 мм, расширяя свободу дизайна. С точки зрения производительности цинковое литьё под давлением отличается короткими циклами и отлично подходит для массового выпуска. Кроме того, высокое качество поверхности «как отлито» часто позволяет использовать детали напрямую или с минимальной доводкой перед нанесением покрытий или сборкой.

Широкие области применения цинковых отливок под давлением

Автомобильная промышленность

В автопроме цинковые отливки под давлением широко применяются для элементов интерьера, систем дверных замков, корпусов датчиков и других компонентов. Эти детали требуют точных размеров, привлекательного внешнего вида и достаточной механической прочности — требования, которые цинковое литьё под давлением выполняет особенно эффективно.

Потребительская электроника и бытовая техника

Потребительская электроника нуждается и в высокой эстетике, и в строгих допусках. От петель ноутбуков до корпусов устройств умного дома — цинковое литьё под давлением обеспечивает и жёсткость конструкции, и премиальное качество поверхности. Хорошие свойства экранирования ЭМП также делают цинк выгодным для электронных корпусов.

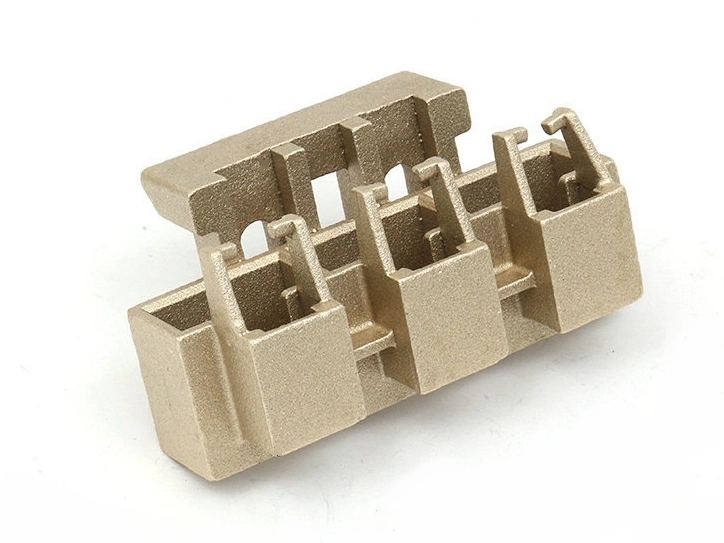

Фурнитура и замковые изделия

Фурнитура и замки — традиционно сильная область цинкового литья под давлением. Ручки, цилиндры замков и связанные компоненты могут производиться со сложной внутренней геометрией и аккуратными внешними формами при сохранении долговечности и надёжности.

Мода и брендовые потребительские товары

В индустрии моды и брендовых товаров мы изготавливали изысканные пряжки ремней и элегантные крышки флаконов духов для известных марок. Эти проекты демонстрируют исключительную совместимость цинкового литья под давлением с финишной обработкой — от зеркального хрома до «винтажных» патинированных эффектов.

Выбирайте Newway для профессиональных решений по литью цинковых сплавов

В Newway мы накопили более десяти лет опыта в литье под давлением цинковых сплавов. Помимо современного производственного оборудования и комплексных систем контроля качества, наша ключевая сила — опытная инженерная команда, обеспечивающая полную техническую поддержку от оптимизации дизайна до массового выпуска. Наши возможности постобработки гарантируют соответствие каждой детали самым высоким стандартам, а модель сервиса «под ключ» позволяет заказчикам сосредоточиться на своём основном бизнесе. Например, комплексное решение по литью и отделке, которое мы реализовали для корпусов электробритв Philips, наглядно демонстрирует наши интегрированные возможности в этой сфере.

Заключение: выбор оптимального производственного процесса для вашего проекта

Как проверенная и надёжная технология, литьё под давлением цинковых сплавов обеспечивает отличный баланс точности, эффективности и стоимости. Будь то массовые промышленные детали или ориентированные на дизайн потребительские продукты — процесс даёт конкурентоспособные и устойчивые решения. Мы рекомендуем разработчикам учитывать возможности цинкового литья под давлением уже на ранних этапах проекта и сотрудничать с профессиональными инженерными командами, чтобы полностью раскрыть преимущества технологии и создавать более конкурентные изделия.

Часто задаваемые вопросы (FAQ)

В чём основные различия между Zamak 3 и Zamak 5? Как выбрать?

Какова минимальная толщина стенки, достижимая при литье под давлением цинкового сплава?

Подходит ли литьё цинкового сплава под давлением для улицы? Какова коррозионная стойкость?

Каков типичный срок производства цинковых отливок под давлением?

Может ли Newway поддержать пробное мелкосерийное производство цинковых отливок под давлением?