Fundición en arena rentable para producción en lotes pequeños

Por qué la fundición en arena sigue siendo la opción más económica para lotes pequeños

Como ingeniero en Neway, trabajo con equipos que necesitan piezas metálicas funcionales con rapidez, sin incurrir en moldes de alto costo ni comprometerse con grandes volúmenes de producción. La fundición en arena demuestra constantemente ser la solución más rentable para la fabricación en lotes pequeños, ya que requiere herramental mínimo, admite geometrías complejas y es compatible con una amplia gama de materiales.

Para empresas en fases tempranas de validación, o para aquellas que producen productos especializados en cantidades limitadas, la fundición en arena reduce significativamente los gastos iniciales. El material del molde—arena compactada—puede conformarse rápidamente y reemplazarse a bajo costo, lo que la hace ideal para corridas piloto, evaluaciones de ingeniería, repuestos de posventa o pedidos comerciales de corta serie.

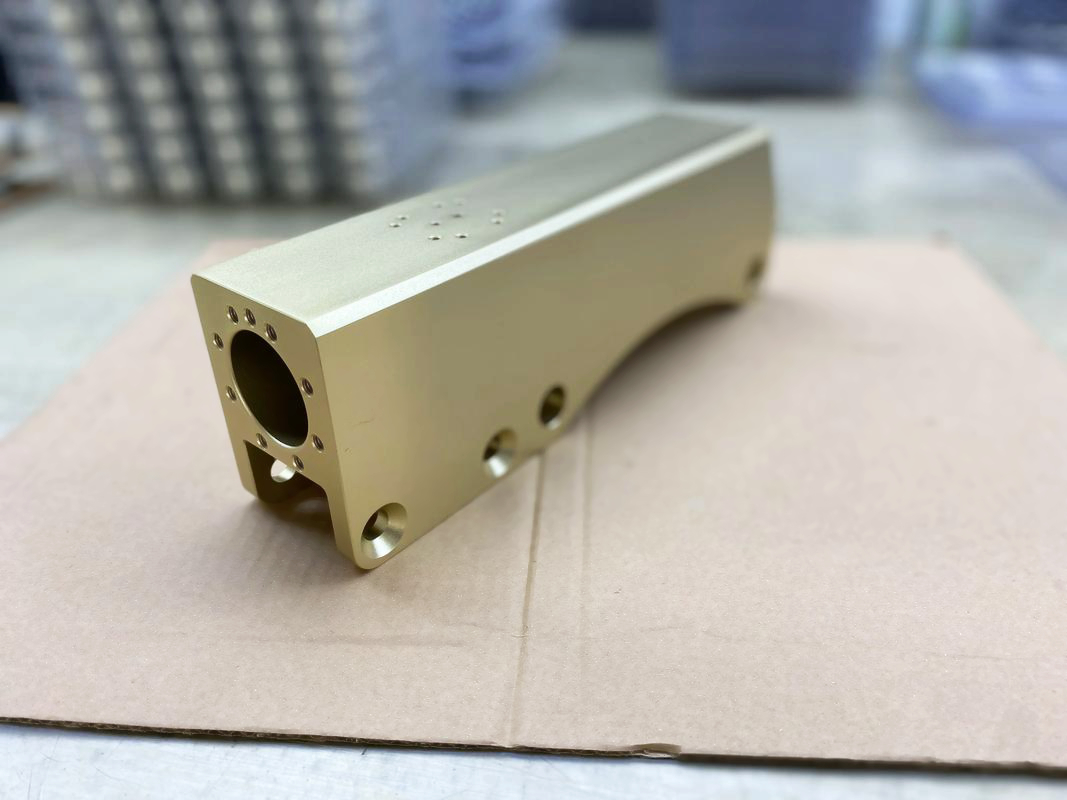

Mediante fundición en arena, producimos con frecuencia piezas que serían mucho más costosas de mecanizar desde tocho o de moldear mediante fundición a presión de alta presión. El proceso admite carcasas complejas, soportes, elementos estructurales y piezas de disipación térmica, manteniendo los costos predecibles y manejables.

Herramental mínimo = máximo ahorro

Los procesos tradicionales de fundición metálica dependen de moldes de acero mecanizados con precisión. Estas herramientas son costosas y requieren mucho tiempo de fabricación, lo que dificulta justificarlas para pedidos pequeños. La fundición en arena evita este problema por completo. El herramental suele incluir patrones simples de madera o impresos, que pueden producirse de forma rápida y económica.

Los equipos de desarrollo a menudo comienzan verificando la geometría mediante prototipado rápido, creando modelos con forma precisa que ayudan a refinar el diseño final del molde. Una vez validada la geometría, el molde de arena se forma alrededor del patrón y se reemplaza después de cada colada. Esta escalabilidad inmediata hace que la fundición en arena sea adecuada para pedidos que van desde unas pocas piezas hasta varios cientos.

Si se necesita mayor precisión, integramos mecanizado CNC para refinar características clave después de la fundición. Este método híbrido mantiene bajo el costo de herramental y, al mismo tiempo, entrega tolerancias de nivel industrial.

Una amplia gama de aleaciones para una producción flexible

La elección de material es una de las ventajas más importantes de la fundición en arena, especialmente para lotes pequeños que requieren propiedades mecánicas específicas. El aluminio sigue siendo la opción más común debido a su equilibrio entre resistencia, peso y colabilidad. Nuestro equipo evalúa con frecuencia las opciones de aleación con los clientes, utilizando recursos como aleaciones de aluminio para encontrar la mejor combinación de rendimiento y costo.

Para aplicaciones que requieren resistencia al desgaste, detalles finos o estabilidad dimensional, los ingenieros suelen explorar aleaciones de zinc. Los metales a base de cobre—referidos como aleaciones de cobre-latón—se prefieren para componentes de transferencia térmica, accesorios, conectores y piezas resistentes a la corrosión.

En situaciones con cargas más exigentes o temperaturas más altas, ciertos materiales para herramental pueden evaluarse para determinar su idoneidad en prototipos funcionales o componentes industriales en etapas tempranas.

Poder elegir entre una gama tan amplia de aleaciones garantiza que los clientes de lotes pequeños reciban piezas que representen de cerca las características finales de producción, sin la carga de herramentales costosos.

Fundición en arena vs. CNC y fabricación aditiva para pedidos de corta serie

En cantidades de lote pequeño, los ingenieros deben elegir entre varias rutas de fabricación. Cada proceso tiene beneficios, pero la fundición en arena suele ofrecer el mejor equilibrio entre costo, geometría y opciones de material.

El mecanizado desde tocho brinda precisión, pero se vuelve costoso cuando hay que remover grandes volúmenes de material. La fabricación aditiva destaca por la libertad geométrica, pero puede enfrentar limitaciones de volumen de construcción, disponibilidad de materiales o restricciones de peso. Para evaluaciones ergonómicas previas a la fundición, la fundición de uretano a veces complementa la fundición metálica, aunque no puede igualar el desempeño estructural de una pieza metálica fundida.

La fundición en arena cubre un vacío esencial. Maneja con facilidad formas grandes, estructuras de pared gruesa y geometrías huecas intrincadas, manteniendo extremadamente bajo el costo de herramental. Una vez fundidas, las piezas pueden mecanizarse, granallarse o recubrirse igual que los componentes producidos en masa.

Para muchos clientes, el mejor enfoque es un flujo híbrido: validación de forma con modelos impresos en 3D mediante impresión 3D, seguida de fundición metálica en lotes pequeños para evaluación funcional. Esto brinda máxima velocidad y rentabilidad durante las etapas iniciales del desarrollo de producto.

Postprocesado para alta precisión y calidad funcional

Incluso en proyectos de lotes pequeños, el acabado superficial y la precisión dimensional son esenciales. Las piezas fundidas en arena pueden requerir mecanizado para lograr las tolerancias necesarias para ensamblaje o superficies de sellado. Esto se gestiona mediante posmecanizado de piezas fundidas cuando se deben refinar detalles finos o características de acoplamiento.

También pueden aplicarse acabados, limpieza o recubrimientos según las necesidades de desempeño. Los procesos agrupados en postprocesado para piezas fundidas—incluyendo granallado, vibrado (tumbling) o recubrimientos protectores—se adaptan con frecuencia a componentes fundidos en arena para mejorar durabilidad o apariencia.

Estas operaciones aseguran que las piezas de lotes pequeños no solo aporten el beneficio del bajo costo de herramental, sino que también cumplan requisitos industriales de desempeño mecánico y acabado.

Aplicaciones industriales que dependen de la fundición en arena de bajo volumen

Las industrias a las que damos soporte en Neway con frecuencia necesitan piezas metálicas de alta calidad en pequeñas cantidades para validación, pruebas o producción limitada. Las empresas automotrices, por ejemplo, usan prototipos fundidos en arena para evaluar carcasas, componentes del tren motriz y estructuras térmicas. Relaciones con proveedores, como las que involucran componentes automotrices, ilustran cuán rápido puede evolucionar un diseño desde el concepto hasta un prototipo funcional.

En aeroespacial, la fundición en arena ofrece un enfoque práctico para probar geometrías y características portantes antes de invertir en herramental permanente para volúmenes mayores. Muchos programas de desarrollo temprano, similares a los flujos de desarrollo de piezas aeroespaciales, aprovechan componentes fundidos en arena para validar diseños críticos de desempeño.

Los fabricantes de electrónica de consumo confían en prototipos fundidos en arena para evaluar bastidores, carcasas o sistemas térmicos antes de comprometerse con herramental de fundición a presión. Ejemplos de colaboración, como los que involucran hardware de electrónica de consumo, muestran cómo la fundición en arena apoya iteraciones rápidas y comparaciones precisas de materiales.

En todos estos sectores, la fundición en arena de lotes pequeños permite a los equipos explorar materiales, optimizar diseños y validar desempeño sin incurrir en altos costos generales.

Cómo elegir el socio adecuado para fundición en arena de lotes pequeños

El éxito de cualquier proyecto de lotes pequeños depende de la experiencia técnica del socio de fundición, su capacidad de proceso y el soporte de ingeniería. En Neway, nuestro equipo de ingeniería guía a los clientes en selección de aleaciones, optimización de geometría, creación de patrones, diseño de canales de colada y control de calidad.

La capacidad de brindar soporte integral—incluyendo DFM, desarrollo de prototipos, mecanizado, acabado y pruebas—asegura repetibilidad entre lotes de producción. La colaboración de ingeniería mediante servicios como servicio de diseño e ingeniería ayuda a los clientes a refinar sus diseños desde temprano, reduciendo costos y mejorando la manufacturabilidad.

Ya sea que el requisito incluya solo unas cuantas piezas o una serie de lotes piloto, la fundición en arena sigue siendo la ruta más económica y flexible para fabricar componentes metálicos durables y funcionales.

FAQs

¿Por qué la fundición en arena es ideal para la fabricación en lotes pequeños?

¿Qué materiales funcionan mejor para la fundición en arena de bajo volumen?

¿Cómo se compara la fundición en arena con el mecanizado CNC y la impresión 3D para series cortas?

¿Qué nivel de precisión se puede lograr con piezas fundidas en arena posmecanizadas?

¿Con qué rapidez se pueden entregar piezas fundidas en arena en lotes pequeños?