Fundición de uretano ideal para geometrías complejas y múltiples materiales

Por qué la fundición de uretano destaca en diseños complejos y multimaterial

Como ingeniero de Neway, trabajo con clientes que desafían los límites de la fabricación todos los días. Muchos equipos nos traen piezas con curvas orgánicas, socavados intrincados, secciones delgadas o ensamblajes que integran múltiples materiales funcionales en un solo prototipo. Los métodos de fabricación tradicionales, como el mecanizado CNC o el moldeo por inyección, pueden tener dificultades con estas geometrías durante el desarrollo temprano. Las restricciones del herramental, los plazos largos y los costos altos dificultan la exploración del diseño.

La fundición de uretano elimina estos obstáculos. El uso de moldes de silicona y patrones maestros digitales permite crear formas complejas que el herramental rígido no puede acomodar. También habilita estrategias creativas multimaterial, permitiendo combinar diferentes durezas (durometrías), colores y características estructurales en un solo prototipo. Para ingenieros que requieren ciclos de aprendizaje rápidos, realismo funcional y libertad para iterar, la fundición de uretano ofrece una flexibilidad inigualable.

En Neway, hemos perfeccionado el proceso en un flujo de trabajo estrictamente controlado—compatible con todo, desde sellos elastoméricos suaves hasta carcasas rígidas, cubiertas resistentes a impactos y ensamblajes de múltiples etapas. El resultado es un método de prototipado versátil que se adapta incluso a las geometrías más exigentes.

La ventaja de usar maestros digitales para formas complejas

La base de una fundición de uretano de alta calidad es la creación del patrón maestro. Según la complejidad, los ingenieros de Neway eligen entre métodos de fabricación aditiva o sustractiva. Cuando las piezas incluyen canales profundos, curvatura orgánica o características internas muy detalladas, normalmente generamos el maestro mediante impresión 3D. Este enfoque maneja la geometría compleja sin restringir la intención del diseñador.

Para prototipos con tolerancias ajustadas, caras de acoplamiento planas o roscas de precisión, en ocasiones usamos CNC para mecanizar el maestro. Los maestros mecanizados ofrecen precisión dimensional de base para que el molde de silicona capture los detalles con exactitud.

Otros clientes solicitan maestros hechos mediante flujos de trabajo híbridos—formas impresas refinadas por mecanizado o acabado superficial. Este método híbrido crea maestros altamente precisos y, al mismo tiempo, admite geometrías creativas que no pueden fresarse por sí solas.

Independientemente del método, el objetivo es el mismo: entregar un maestro que represente completamente la intención final. Una vez terminado, el maestro se utiliza para crear un molde de silicona blando y flexible que libera fácilmente formas complejas.

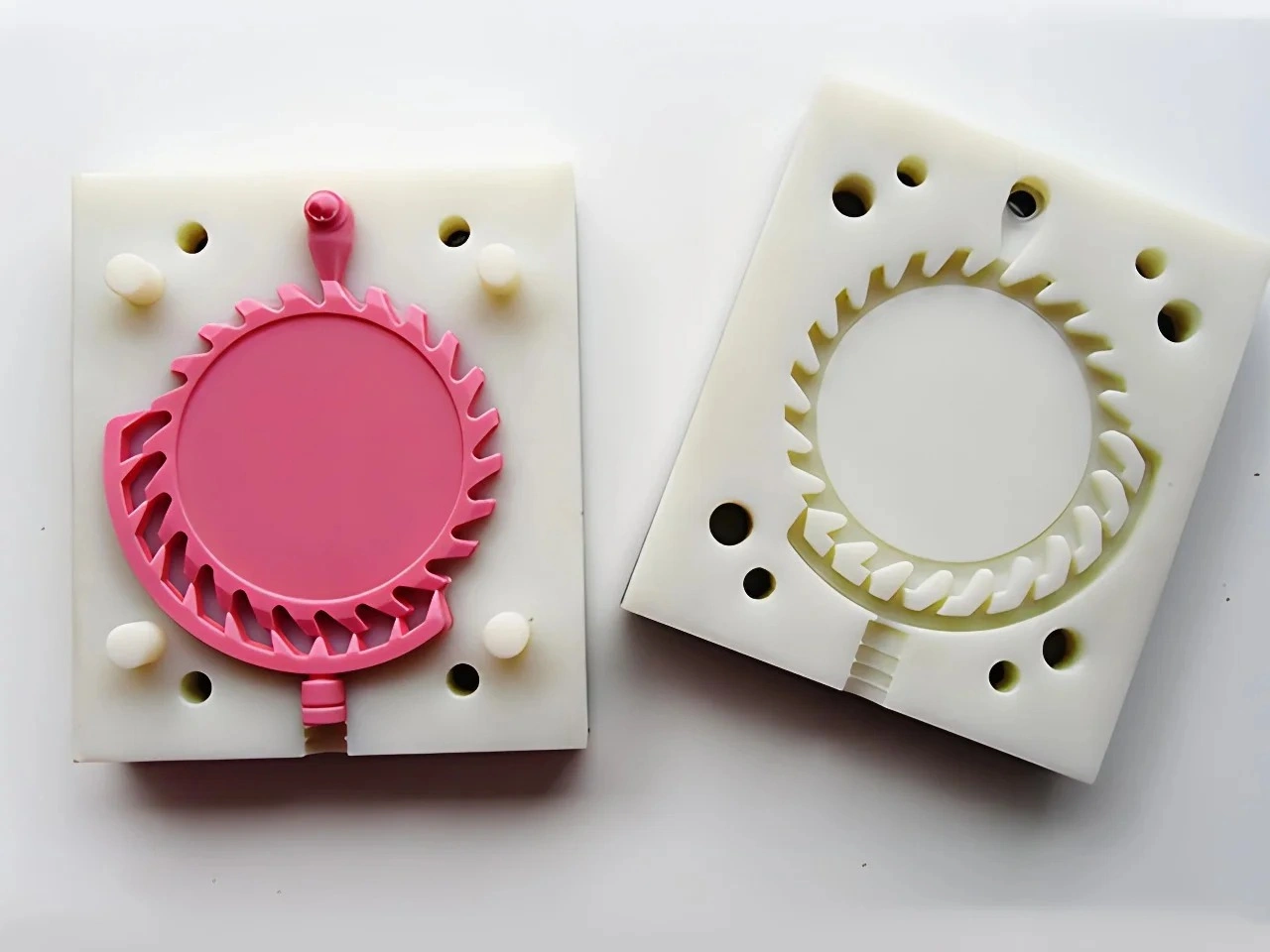

Por qué los moldes de silicona capturan tan bien la geometría compleja

Los moldes de silicona son el núcleo de la adaptabilidad de la fundición de uretano. A diferencia del herramental metálico, los moldes de silicona se deforman ligeramente durante el desmoldeo, lo que permite colar geometrías intrincadas—como socavados, ganchos, formas cerradas y nervaduras internas—sin necesidad de correderas o núcleos metálicos complejos. Esta flexibilidad elimina las restricciones mecánicas que normalmente limitan la libertad de diseño en etapas tempranas.

Cuando los equipos exploran formas similares a estudios tempranos de prototipado rápido o planean una fundición futura en metales como aleaciones de aluminio o aleaciones de zinc, los moldes de silicona aportan información inmediata sobre la manufacturabilidad y el comportamiento estructural de estas geometrías. Las pruebas tempranas con fundición de uretano suelen conducir a decisiones mejor fundamentadas al pasar posteriormente a moldes de inyección o herramental de fundición a presión.

Para clientes que trabajan con componentes metálicos finales—including aleaciones mostradas en aleaciones de cobre-latón—los prototipos de uretano permiten a los diseñadores refinar estructuras internas, patrones de nervaduras y curvatura estética mucho antes de invertir en herramental permanente fabricado con metales similares a materiales para herramental.

Capacidades multimaterial: rígido, flexible y todo lo intermedio

Una de las mayores fortalezas de la fundición de uretano es la amplia gama de químicas de poliuretano disponibles. Estos materiales simulan desde gomas suaves tipo silicona hasta plásticos de ingeniería de alto impacto, permitiendo pruebas funcionales mucho antes de la producción en masa.

Los prototipos pueden replicar: • rigidez tipo ABS • tenacidad tipo PC • flexibilidad tipo PP • sellos y juntas elastoméricas • ensamblajes de materiales mixtos (blando sobre núcleos rígidos)

Las variaciones en color, transparencia, dureza, peso y resistencia mecánica permiten a los diseñadores explorar un espectro de comportamientos. Las secuencias de colada multi-etapa también permiten crear piezas de doble durometría o interfaces adheridas—algo extremadamente difícil y costoso de lograr con moldeo por inyección en etapas tempranas.

Esta flexibilidad es especialmente valiosa en industrias como robótica, dispositivos médicos o electrónica de consumo, donde los diseñadores deben equilibrar el comportamiento mecánico con la sensación táctil. Los prototipos se pueden probar en impacto, agarre, comodidad ergonómica, carga mecánica y tolerancias de ensamble.

Geometría compleja sin herramental costoso

Los moldes de inyección tradicionales requieren ingeniería cuidadosa para considerar líneas de partición, ángulos de desmoldeo, compuertas y expulsión. En geometrías intrincadas, las herramientas pueden requerir múltiples correderas o núcleos colapsables, lo que incrementa notablemente el costo y el tiempo de fabricación. La fundición de uretano evita todas estas limitaciones.

Los moldes de silicona se adaptan a la geometría en lugar de obligar a la geometría a adaptarse a las reglas del herramental. Esto significa que características como: • secciones delgadas • canales profundos • contornos agresivos • clips integrados • cavidades cerradas • formas con voladizos

pueden producirse desde CAD sin restricciones severas. Para equipos que evalúan formas destinadas a fundición en arena o fundición a presión, la fundición de uretano permite explorar geometría rápidamente mucho antes de que el herramental costoso esté justificado.

Al eliminar las restricciones del herramental, los diseñadores iteran más rápido, prueban con mayor profundidad y avanzan hacia la producción final con confianza.

Acabado tipo producción para validación funcional

Después de la colada, los prototipos se someten a postprocesos personalizados según necesidades cosméticas, requisitos funcionales y alineación de ensamble. Los ingenieros de Neway refinan superficies mediante recorte, pulido, simulación de textura y mecanizado localizado. Cuando se requiere precisión dimensional, aplicamos técnicas similares al posmecanizado de piezas fundidas para garantizar exactitud.

Los tratamientos superficiales reflejan expectativas de nivel producción. Pasos de acabado comparables a los usados en postproceso para piezas fundidas a presión pueden aplicarse a piezas de uretano, incluyendo pintura, recubrimiento, lijado o texturizado. Estas técnicas ayudan a los clientes a evaluar la apariencia estética antes de comprometer estándares cosméticos en el herramental posterior.

Para ensamblajes que imitan versiones tempranas de componentes automotrices o productos de consumo similares a hardware de electrónica de consumo, la fundición de uretano proporciona prototipos funcionales que se ven, se comportan y se ensamblan como piezas de producción.

Velocidad, precisión y flexibilidad de material para necesidades industriales

La fundición de uretano ofrece todas las cualidades que los equipos de producto modernos necesitan durante el desarrollo temprano: • entrega rápida • soporte para formas complejas • múltiples comportamientos de material • alta calidad superficial • bajo costo inicial • revisiones de diseño sencillas

Esto la hace ideal para industrias con ciclos de iteración rápidos o requisitos funcionales complejos. Los equipos automotrices se benefician al probar plásticos interiores o estructurales antes de pasar al moldeo por inyección. Los desarrolladores de electrónica de consumo dependen del uretano para validar sensación de agarre, curvatura ergonómica y ajuste de piezas. Los ingenieros que desarrollan herramientas industriales o dispositivos wearables aprovechan la flexibilidad de doble material para ensamblajes de etapa temprana.

En Neway, muchos de nuestros clientes combinan la fundición de uretano con colaboración experta a través de nuestro equipo de servicio de diseño e ingeniería. Juntos evaluamos escalabilidad a largo plazo, modelos de costo y manufacturabilidad, asegurando que la fase de prototipado se alinee perfectamente con la producción futura.