¿Qué es el prototipado mediante fundición de uretano?

Comprender la fundición de uretano en el desarrollo moderno de productos

Como ingeniero de Neway, colaboro con equipos para desarrollar productos en diversas industrias, incluyendo electrónica de consumo, automoción, sistemas industriales y dispositivos médicos. Muchos de estos equipos necesitan prototipos funcionales rápidos que se parezcan a las piezas de producción en apariencia y comportamiento, pero que no justifiquen el tiempo y el costo asociados a un herramental completo de moldeo por inyección. El prototipado mediante fundición de uretano suele ser la respuesta perfecta.

La fundición de uretano (también conocida como colada al vacío de poliuretano) es un método de fabricación de bajo volumen que utiliza moldes de silicona y resinas de poliuretano para crear prototipos altamente realistas. El proceso es especialmente adecuado cuando los clientes necesitan piezas que simulen plásticos, como ABS, PC, PP o elastómeros tipo caucho, todo ello sin necesidad de costosos moldes de acero.

Este enfoque cierra la brecha entre los modelos de diseño temprano y la producción completa. Produce prototipos visualmente refinados y dimensionalmente precisos que ayudan a los equipos a validar geometría, ensamblaje, experiencia de usuario y comportamiento funcional mucho antes de comprometerse con moldes de producción en masa.

Construcción del patrón maestro: la base de todo prototipo de uretano

Cada proyecto de fundición de uretano comienza con un patrón maestro: un modelo físico de alta calidad creado directamente a partir de los datos CAD del cliente. El maestro determina la precisión, el acabado superficial y la fidelidad de cada pieza colada, por lo que su calidad es esencial.

En Neway, empleamos diversos métodos para crear patrones maestros, según la complejidad del diseño y los requisitos de precisión. Para formas complejas u orgánicas, a menudo creamos el maestro mediante impresión 3D. Esto nos permite replicar detalles intrincados sin limitar la geometría del diseñador.

Cuando un cliente necesita tolerancias ajustadas o una superficie de calidad espejo en caras de acoplamiento, podemos mecanizar el maestro mediante mecanizado CNC. Los maestros mecanizados son extremadamente precisos e ideales cuando el molde de silicona debe capturar bordes vivos, roscas o superficies estéticas suaves.

En algunos casos, combinamos métodos aditivos y sustractivos: imprimimos en 3D la forma base y mecanizamos características funcionales para lograr el mejor equilibrio entre velocidad y precisión.

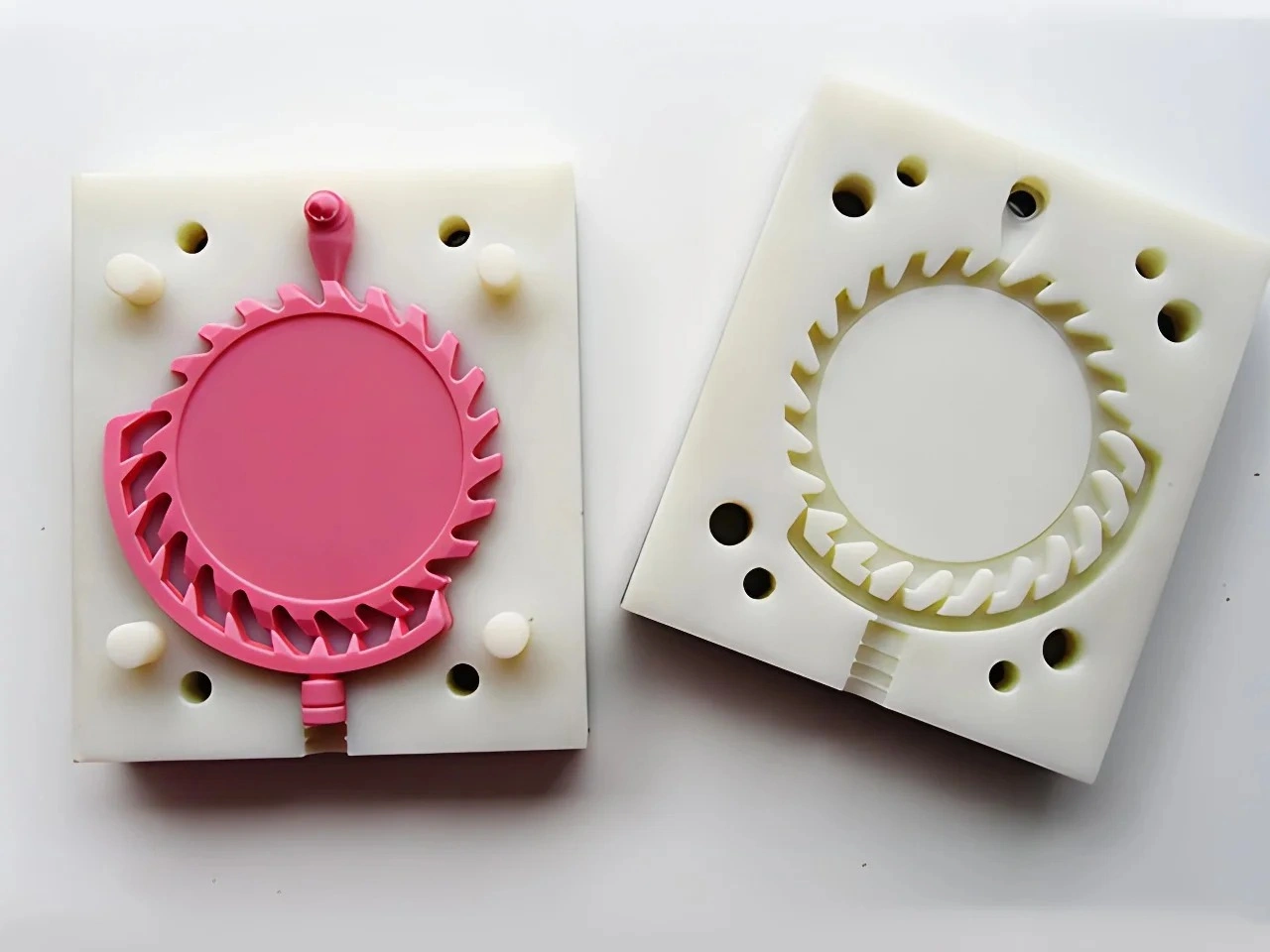

Creación del molde de silicona: flexible, rápida y precisa

Una vez finalizado el maestro, creamos un molde de silicona alrededor de él. La silicona es flexible, duradera y adecuada para producción de bajo volumen, capaz de capturar detalles extremadamente finos como texturas, micro-radios y ángulos de desmoldeo sutiles.

Los moldes de silicona son especialmente beneficiosos para equipos que aún están refinando formas complejas exploradas originalmente mediante prototipado rápido. Su flexibilidad les permite liberar socavados, estructuras huecas o canales profundos sin necesidad de correderas de acero complicadas o herramentales multipieza.

El molde de silicona se convierte en una herramienta reutilizable para colar piezas de poliuretano. La mayoría de los moldes de silicona pueden producir entre 15 y 30 piezas (shots) según la geometría, lo que los hace ideales para pruebas tempranas de usuario, builds de ingeniería, muestras para inversores y verificación preproducción.

Materiales de poliuretano: simulación de los plásticos finales de producción

Una de las razones por las que la fundición de uretano es tan valiosa es su versatilidad de materiales. Las resinas de poliuretano están disponibles en una amplia gama de durezas, texturas, resistencias mecánicas y colores. Esto nos permite simular materiales desde carcasas rígidas hasta elastómeros suaves.

Los ingenieros comparan con frecuencia las propiedades del poliuretano colado con las utilizadas en diversos métodos de producción. Por ejemplo, equipos que trabajan en componentes fundidos a presión pueden evaluar comportamientos similares a los de aleaciones de aluminio o aleaciones de zinc en etapas tempranas del diseño. Cuando los proyectos requieren niveles de rendimiento metálico para producción posterior, algunos terminan transitando hacia aleaciones como las de aleaciones de cobre-latón.

La gama de opciones de poliuretano permite: • simulación de plásticos rígidos • piezas flexibles tipo caucho • estructuras de doble durometría • materiales transparentes o teñidos • carcasas resistentes a impactos

Esta versatilidad hace que la fundición de uretano sea ideal para pruebas ergonómicas, evaluación funcional y aprobaciones estéticas.

Prototipado multimaterial y estilo sobremoldeo

La fundición de uretano también admite prototipos multimaterial, algo que sería costoso y lento con el moldeo por inyección en etapas tempranas. Al colar un material dentro o alrededor de otro, podemos replicar sobremoldeo, insert molding o diseños de doble durometría.

Esto permite a los equipos probar: • texturas de agarre en carcasas rígidas • almohadillas suaves sobre bastidores duros • interfaces de juntas • conceptos estructurales multicapa

Cuando los proyectos finalmente pasan a herramentales de inyección o fundición a presión, nuestro equipo de ingeniería revisa estrategias de tooling usando directrices consistentes con las de materiales para herramental para asegurar que el comportamiento del prototipo se alinee con la viabilidad de producción a largo plazo.

Bajo costo inicial y ciclos de iteración rápidos

Quizá la mayor ventaja de la fundición de uretano es el bajo costo de herramental. Los moldes de silicona son significativamente más baratos y rápidos de producir que los moldes de inyección de aluminio o acero. Esto permite a los equipos revisar diseños múltiples veces sin acumular grandes gastos de tooling.

Como los moldes de uretano son económicos de reemplazar, los ingenieros pueden refinar la geometría libremente—una ventaja esencial para proyectos que aún exploran factor de forma, ergonomía o estructura interna.

Para clientes que evalúan componentes metálicos, a menudo combinamos la fundición de uretano con evaluaciones tempranas realizadas mediante fundición en arena, lo cual es especialmente útil cuando los productos futuros requieren fundición a presión de aluminio o zinc.

El ciclo rápido de la fundición de uretano permite responder con agilidad a cambios de diseño, feedback de pruebas de usuario o sugerencias de inversores.

Acabado de alta calidad para una apariencia tipo producción

Las piezas de uretano pueden acabarse para lucir casi idénticas a componentes moldeados por inyección o fundidos a presión. El refinado superficial, texturizado, imprimación y pintura permiten que los prototipos coincidan con los requisitos cosméticos finales.

Cuando la precisión dimensional es esencial, utilizamos métodos de mecanizado similares al posmecanizado de piezas fundidas para asegurar que características críticas de tolerancia—como taladros, caras de alineación, roscas e interfaces de montaje—queden perfectas.

Para superficies que requieren brillo, color o textura altamente consistentes, incorporamos estrategias de acabado comparables a las de postproceso para piezas fundidas a presión. Muchos clientes confían en estos prototipos de calidad producción para ferias, fotografía, presentaciones a inversores y demostraciones tempranas a clientes.

Una opción ideal para muchas industrias

La fundición de uretano es compatible con industrias que requieren prototipos rápidos y realistas, incluyendo: • electrónica de consumo • interiores automotrices • instrumentación industrial • dispositivos médicos • robótica y wearables

Los equipos que preparan componentes similares a componentes automotrices usan prototipos de uretano para validar comportamiento de ensamble y calidad superficial antes de construir moldes de inyección. Los diseñadores de electrónica de consumo que desarrollan carcasas, como las de hardware de electrónica de consumo, dependen de la fundición de uretano para texturas realistas y pruebas ergonómicas.

A lo largo del desarrollo, muchos clientes colaboran con nuestro equipo de servicio de diseño e ingeniería para asegurar que el prototipo se alinee con estrategias de fabricación a largo plazo, objetivos de costo y expectativas de rendimiento de material.

FAQs

¿Cuáles son los principales beneficios de la fundición de uretano para prototipado?

¿Cómo ayuda la colada en molde de silicona a soportar geometrías complejas?

¿Qué materiales puede simular la fundición de uretano para pruebas funcionales?

¿Cuántas piezas se pueden producir con un solo molde de silicona?