Neway のエンジニアリング能力

オンライン カスタムコンポーネント エンジニアリングサービス

Neway のオンライン カスタムコンポーネント エンジニアリングサービスは、設計最適化、材料選定、先進シミュレーションを組み合わせて部品性能を高めます。構造解析、応力試験、製造プロセス改善を提供し、カスタム部品が最高水準の品質と効率を満たすようにします。

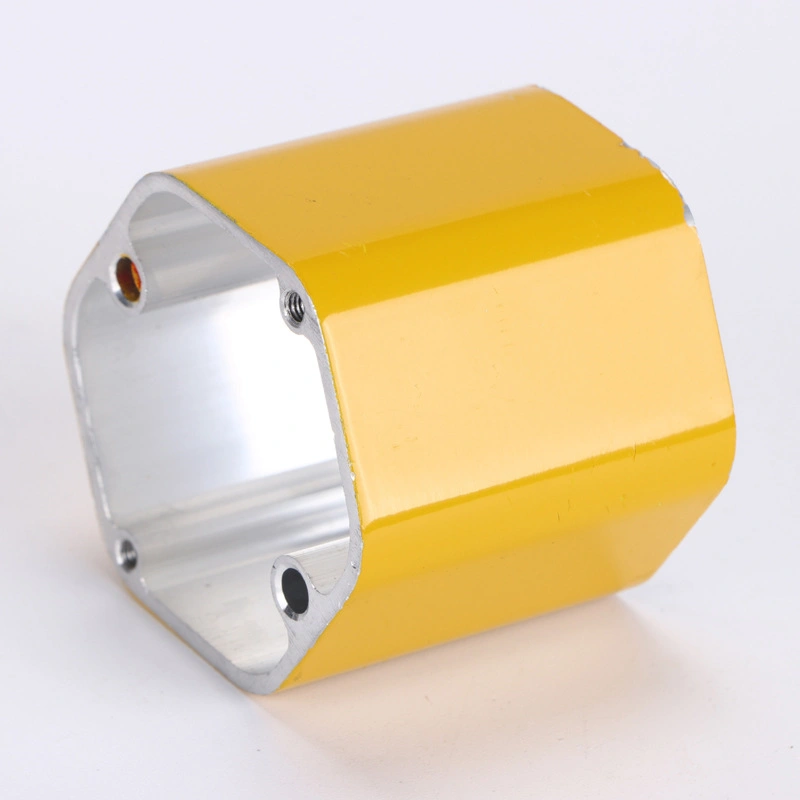

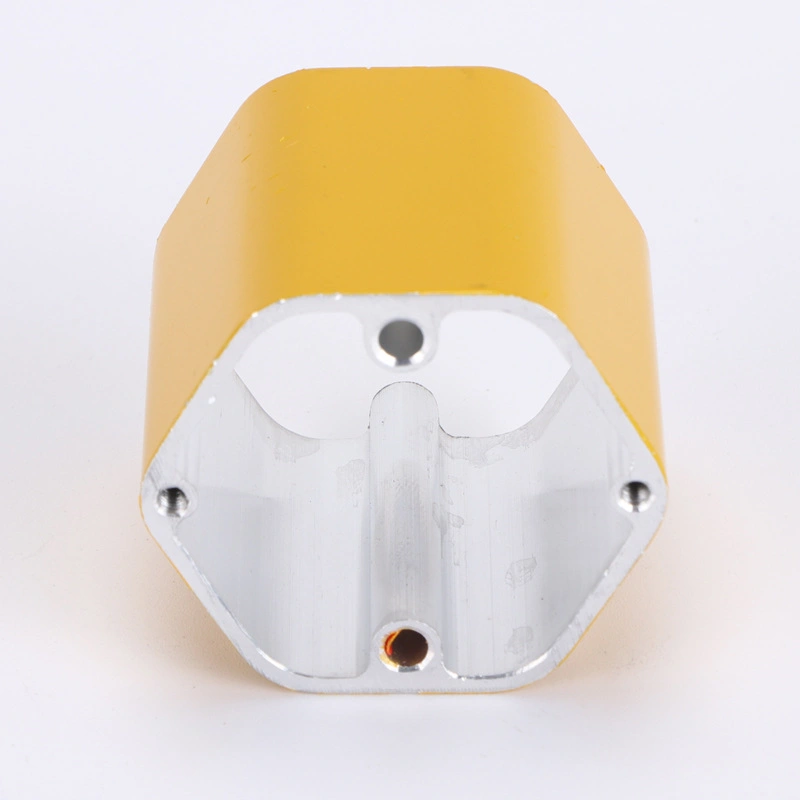

金属鋳造 - カスタムコンポーネント エンジニアリング

アルミダイカスト、亜鉛ダイカスト、銅ダイカスト、金型・治工具製作に特化した、金属鋳造産業向けオンライン カスタムコンポーネント エンジニアリングサービスを提供します。あらゆるプロジェクトで精度、耐久性、効率を実現します。

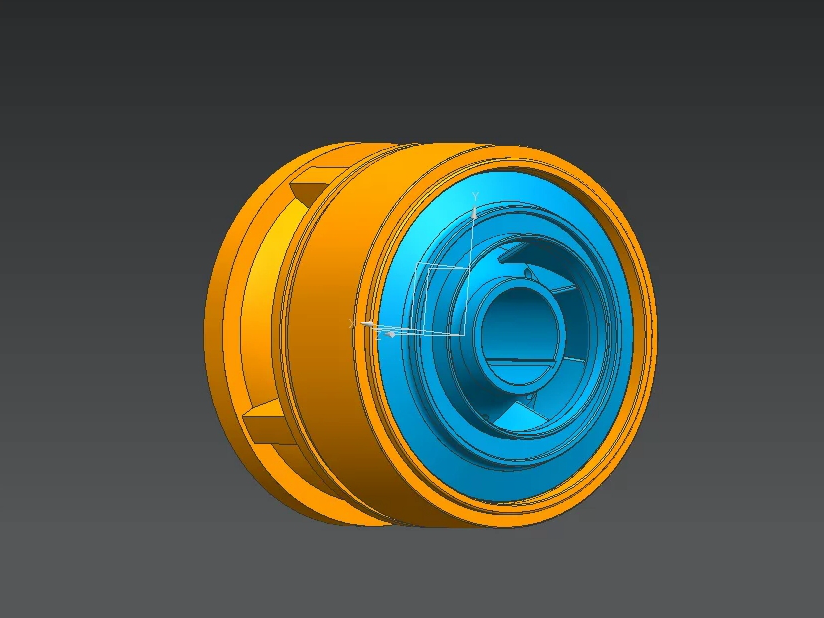

ラピッドプロトタイピング - カスタムコンポーネント エンジニアリング

CNC 加工、3D プリント、ウレタン鋳造、砂型鋳造などのラピッドプロトタイピング向けオンライン カスタムコンポーネント エンジニアリングサービスを提供。短納期・高精度・高コスト効率で製品開発と製造イノベーションを加速します。

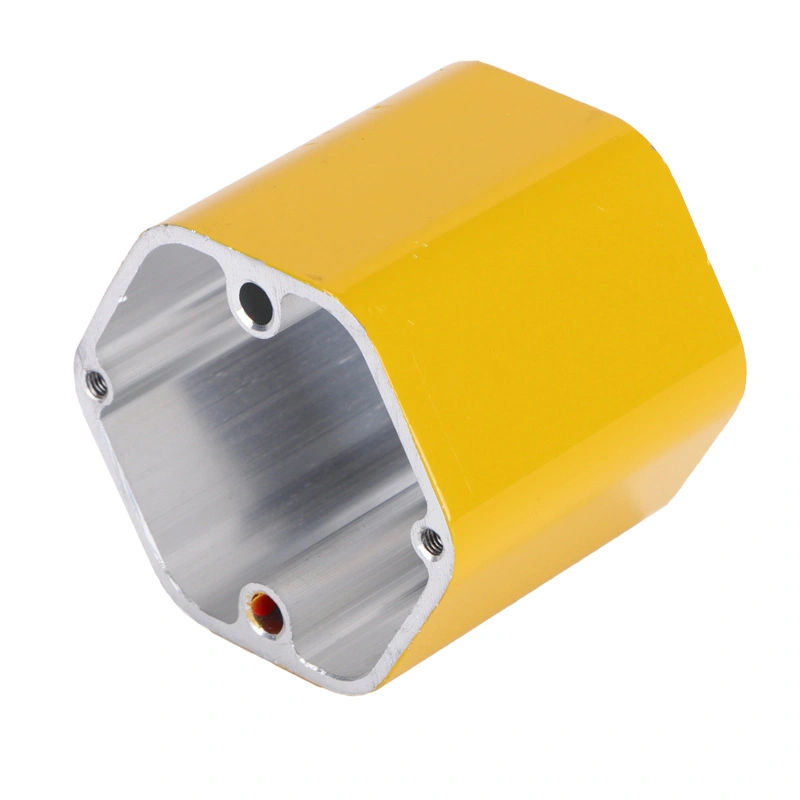

後工程(ポストプロセス) - カスタムコンポーネント エンジニアリング

機械加工、ブラスト、コーティング、アセンブリなどの後工程向けオンライン カスタムコンポーネント エンジニアリングサービスを提供し、高品質な外観と耐久性を実現します。

鋳造材料 - カスタムコンポーネント エンジニアリング

アルミ合金、亜鉛合金、銅合金、工具材料などの鋳造材料に対するオンライン カスタムコンポーネント エンジニアリングサービスを提供。最適な材料選定により、強度・耐久性・性能を最大化します。

本日新しいプロジェクトを開始しましょう

Frequently Asked Questions

関連リソースを探索

Copyright © 2026 Diecast Precision Works Ltd.All Rights Reserved.