Neway のプロトタイピング能力

オンライン カスタムコンポーネント 試作サービス

Neway のオンライン カスタムコンポーネント試作サービスは、迅速かつ高精度な試作ソリューションを提供します。先進の3DプリントとCNC技術を活用し、設計検証、材料選定、機能試験を通じて、量産前に部品が性能基準を満たすことを確実にします。

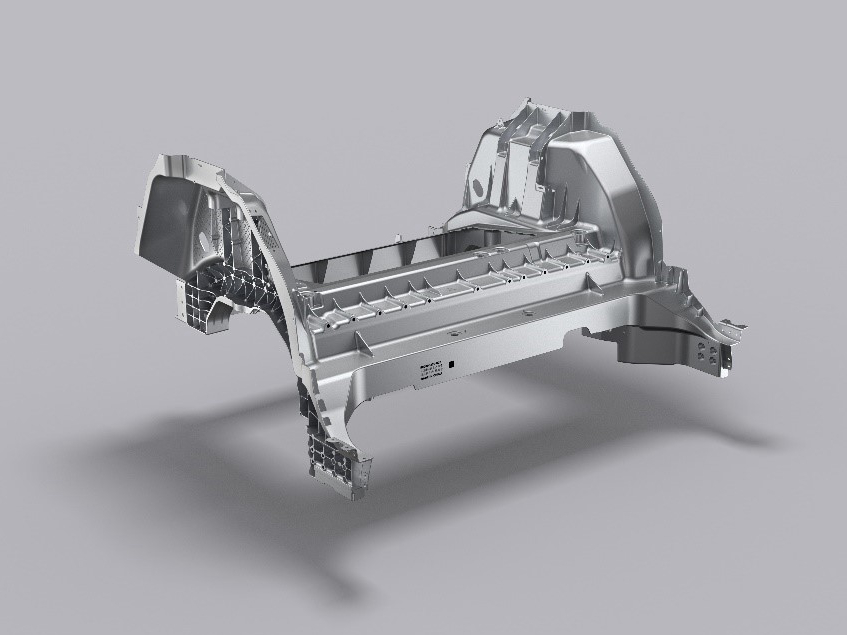

金属鋳造 - カスタムコンポーネントの試作

アルミ、亜鉛、銅のダイカストおよび金型製作を含む、金属鋳造のカスタムコンポーネント試作サービスに特化。多様な産業用途に向け、精度、耐久性、コスト効率に優れた先進の試作ソリューションを提供します。

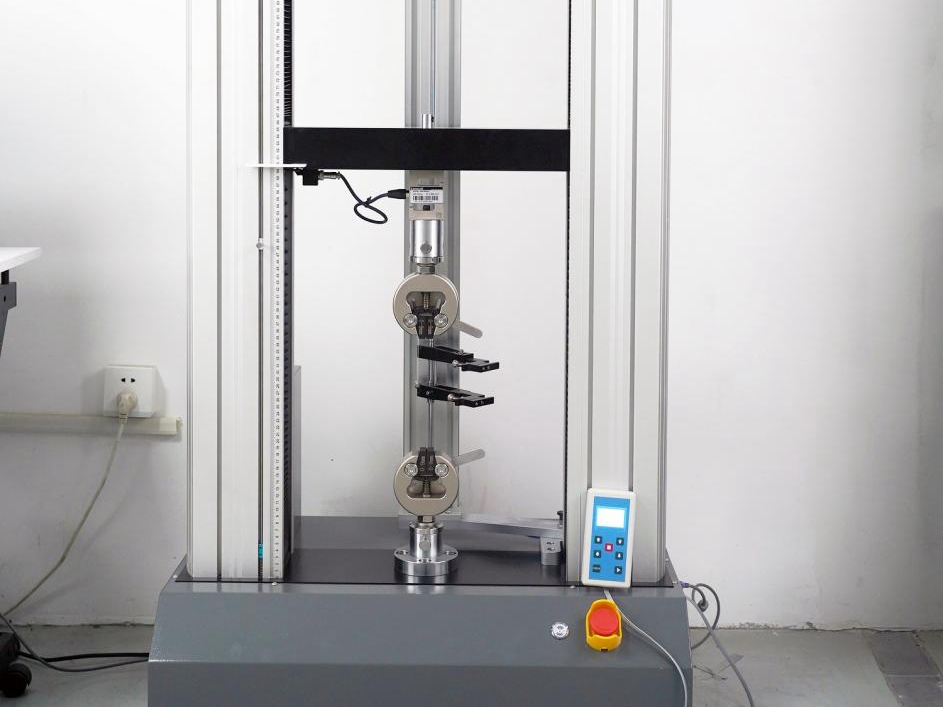

ラピッドプロトタイピング - 高精度試作 & 試験

CNC加工、3Dプリント、ウレタン鋳造、砂型鋳造を含む先進のラピッドプロトタイピングを提供。機能試験、小ロット試作、反復設計改善を支援し、多様な産業用途向けに高精度プロトタイプを実現します。

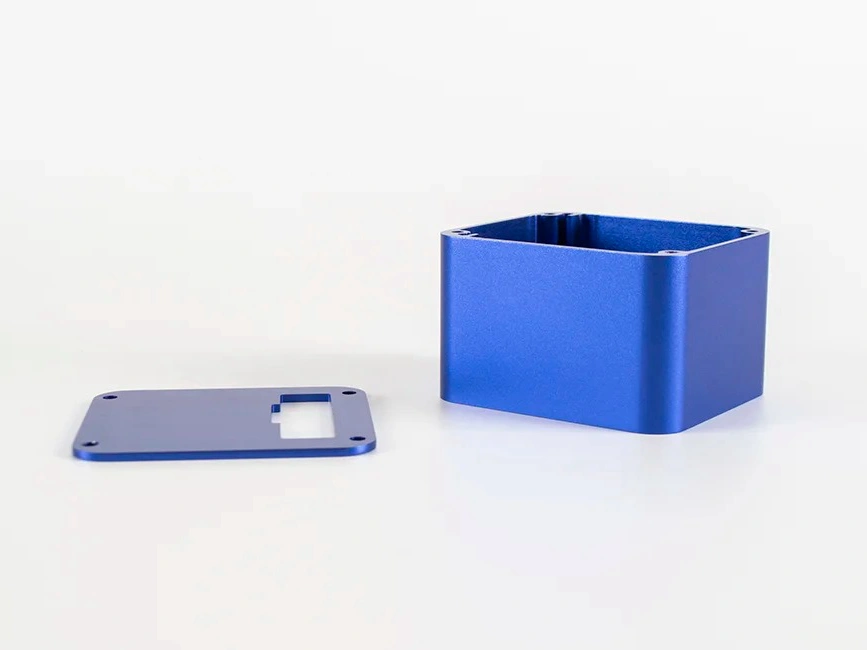

ポストプロセス - カスタムコンポーネント試作

オンラインのカスタムコンポーネント試作におけるポストプロセスを提供し、精度、耐久性、優れた外観を実現。ラピッド試作、機能試験、小ロット試作、反復設計改善を強力にサポートします。

鋳造材料 - カスタムコンポーネント試作

アルミニウム合金、亜鉛合金、銅合金、工具材料の材料選定に特化したオンライン試作サービスを提供。ラピッド試作、機能試験、小ロット試作、反復設計改善を支援し、高性能部品の実現を後押しします。

本日新しいプロジェクトを開始しましょう

Frequently Asked Questions

関連リソースを探索

Copyright © 2026 Diecast Precision Works Ltd.All Rights Reserved.